What is the process of sheet metal?

Release time:

2024-12-17

In-depth exploration of the sheet metal processing process, starting from design and drawing, through key steps such as cutting, bending, welding and surface treatment. Zhuhai Chuntian Machinery has significant advantages in this field. With superb skills and excellent equipment, it strictly controls each process, produces high-quality sheet metal parts in the machinery, electronics and other industries, sets industry benchmarks, and leads the new trend of processing.

In modern manufacturing, sheet metal processing is an extremely important process, which is widely used in many fields such as machinery manufacturing, electronic equipment, and the automotive industry. So, what is the process flow of sheet metal processing?

The first step of sheet metal processing is design and drawing. According to the functional requirements and appearance requirements of the product, technicians use professional CAD software to make precise design drawings to determine the shape, size, hole location and other detailed information of the sheet metal parts. This link is like a blueprint for a building, providing precise guidance for subsequent processing. For example, when designing the shell of an electronic device, it is necessary to consider the layout of internal components, heat dissipation requirements, and the convenience of human-computer interaction, and design a reasonable sheet metal structure.

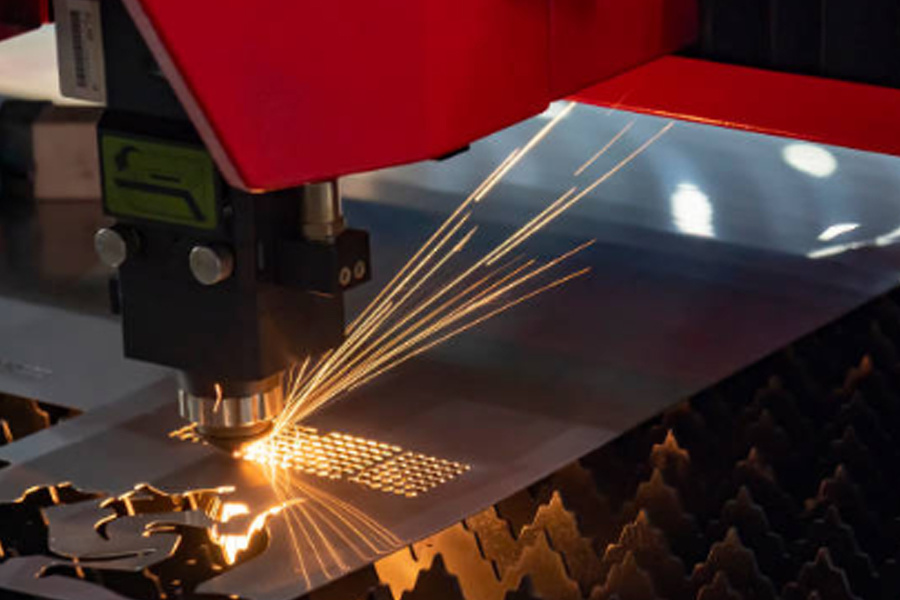

Next, enter the blanking process. Commonly used blanking methods include shearing machine blanking, laser cutting blanking, CNC punch blanking, etc. Shearing machine blanking is suitable for straight-line cutting of sheets, and can quickly cut large sheets into the required width and length; laser cutting blanking has the characteristics of high precision and high flexibility, and can cut sheet metal parts of complex shapes, with smooth cutting surfaces and small heat-affected zones, and is often used to process precision sheet metal products; CNC punch blanking can quickly punch holes and contours of various shapes on the sheet through programming to improve production efficiency. Zhuhai Chuntian Machinery has advanced blanking equipment, which can select the most suitable blanking method according to different sheet metal processing requirements to ensure the accuracy and efficiency of blanking.

After blanking is completed, the bending process is the process of bending. Bending is the process of bending a flat sheet metal part into a specific angle and shape. This requires a professional bending machine. The operator adjusts the mold and parameters of the bending machine according to the drawing requirements, such as the bending angle, bending radius, etc., to accurately bend the sheet metal part. In this process, the experience and skills of the operator are crucial. They need to accurately control the force and position of the bending to ensure the dimensional accuracy and shape accuracy of the sheet metal part. Zhuhai Chuntian Machinery's bending technicians have undergone rigorous training and are able to skillfully operate bending machines to process bent sheet metal parts that meet various precision requirements.

Then comes the welding process. For some complex sheet metal structures, multiple sheet metal parts need to be welded together. Welding methods include argon arc welding, carbon dioxide shielded welding, etc. When welding, the strength, sealing and aesthetics of the weld must be ensured. After welding, grinding may also be required to remove burrs and unevenness of the weld. Zhuhai Chuntian Machinery's welding team strictly follows the welding process standards, uses high-quality welding materials and advanced welding technology to ensure the reliability of welding quality.

Finally, there is the surface treatment process. This can improve the corrosion resistance and aesthetics of sheet metal parts. Common surface treatment methods include painting, electroplating, phosphating, etc. Painting can provide sheet metal parts with a rich color selection while protecting them from environmental erosion; electroplating can form a layer of metal plating on the surface of sheet metal parts to enhance their wear resistance and decorativeness; phosphating is mainly used to improve the coating adhesion of sheet metal parts. Zhuhai Chuntian Machinery selects appropriate surface treatment processes according to customer needs and the product's use environment to achieve the best performance and appearance of sheet metal parts.

The process of sheet metal processing covers multiple links such as design drawing, cutting, bending, welding, and surface treatment. Zhuhai Chuntian Machinery, with its advanced equipment, professional technical team and rigorous quality control system, can provide customers with high-quality and high-precision sheet metal products in the field of sheet metal processing, meet the diverse needs of different industries, and play an important role in the manufacturing industry.

Key Words