Sheet metal processing for medical equipment: process difficulty and product added value

Release time:

2025-01-24

Medical equipment sheet metal processing requires high-precision material selection and process, with high costs but also high added value. Process difficulty and added value are interdependent and contradictory, and companies need to balance market demand, cost and product quality to maximize benefits.

In the field of sheet metal processing, due to its particularity, there is a complex and contradictory relationship between the process difficulty and the added value of products in medical equipment sheet metal processing. Compared with other fields such as energy storage sheet metal processing and automotive machinery parts processing, medical equipment sheet metal processing has unique requirements.

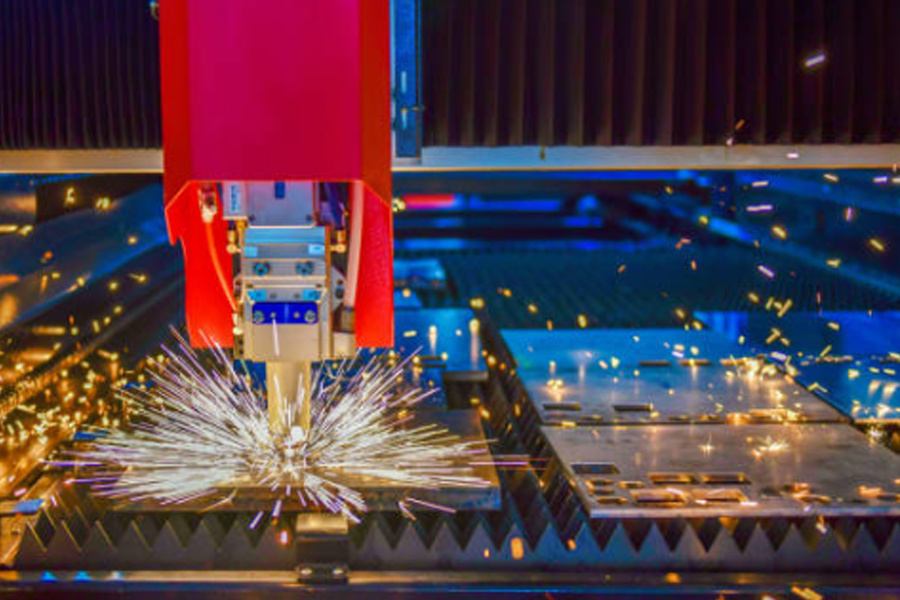

Let's first look at the process difficulty of medical equipment sheet metal processing. Medical equipment is related to the life and health of patients, and has extremely high requirements for precision and quality. From the material selection, special materials that meet the biocompatibility standards must be selected to ensure that there will be no adverse effects on the human body, which is significantly different from the material selection of ordinary sheet metal processing. In the processing process, precise cutting, bending, welding and other processes are indispensable. For example, when making the shell of a CT machine, the joint gaps of each component are required to be extremely small to ensure the electromagnetic shielding effect of the equipment and the overall aesthetics of the appearance. This requires extremely precise cutting and welding processes, and any slight error may lead to a decrease in equipment performance. Moreover, the shapes of medical equipment are often complex and diverse. For example, some structural parts inside medical devices require multiple complex bending and forming processes, which require extremely high technical levels for processing equipment and operators.

However, high process difficulty also brings about a significant increase in costs. High-precision processing equipment is expensive and has high maintenance costs, requiring professional technicians to perform regular maintenance and calibration. At the same time, the investment in skill training for operators is also large. It takes a lot of time and energy to train a worker who is proficient in the sheet metal processing technology of medical equipment. The increase in these costs directly affects the production price of the product.

Let's look at the added value of the product. Due to the importance and particularity of medical equipment, its product added value is often high. Once the sheet metal parts of medical equipment can meet strict quality and performance requirements, it can provide strong guarantees for the safety, stability and functionality of the entire medical equipment, thereby improving the competitiveness and price of the equipment in the market. For example, the finely processed medical equipment shell can not only protect the internal precision electronic components, but also improve the appearance and user experience of the equipment, thereby increasing the added value of the product. Moreover, the replacement of medical equipment is relatively slow. Once a product is recognized in the market, it may maintain stable sales for a long time, bringing continuous profits to the company.

But the contradiction is also obvious. On the one hand, in order to reduce costs, companies may reduce the difficulty of the process to a certain extent, such as using relatively low-precision equipment or reducing the investment in operator training, which may lead to a decline in product quality and thus reduce the added value of the product. On the other hand, if we blindly pursue high added value and continuously increase the difficulty of the process, the cost will continue to rise. Excessively high product prices may reduce market demand and affect the economic benefits of the enterprise. Compared with energy storage sheet metal processing, energy storage equipment is more sensitive to cost control, while medical equipment pays more attention to safety and precision; compared with automobile mechanical parts processing, automobile parts processing focuses more on mass production and efficiency, while medical equipment sheet metal processing emphasizes personalized customization and high precision.

In the sheet metal processing of medical equipment, the process difficulty and product added value are both interdependent and contradictory. In actual production, enterprises need to comprehensively consider factors such as market demand, cost control and product quality, and find the best balance between process difficulty and product added value, so as to maximize economic benefits while ensuring product quality.

Key Words