Stamping process optimization in automobile chassis sheet metal processing

Release time:

2025-02-14

The stamping process of automobile chassis is complex, involving five processes: blanking, drawing, trimming, punching, and shaping. High-strength stainless steel materials need to improve utilization and efficiency by optimizing the layout of draw ribs and the intelligent insert system. In terms of process parameter control, a servo hydraulic system is used to adjust the blanking force in real time to reduce the risk of hardening.

The car chassis is known as the "steel skeleton" of the vehicle, and its sheet metal stamping parts account for more than 30% of the weight of the vehicle. From longitudinal beams, beams to suspension supports, the molding of each part needs to go through five processes: blanking - drawing - trimming - punching - shaping. In the field of stainless steel sheet metal processing, this process is more challenging because of the high strength and easy hardening characteristics of the material.

The three main battlefields of stamping optimization

1. The "millimeter war" of mold design

- The magic of the drawbar: In the stamping of the chassis longitudinal beam, the surface of the die adds a wavy drawbar, which makes the stainless steel plate evenly stretch and avoid wrinkling by locally increasing the material flow resistance. A Japanese car company increased the material utilization rate from 68% to 75% by optimizing the layout of the drawbar.

- Intelligent insert system: Modular mold design is adopted to meet the needs of multi-vehicle collinear production. For example, the Tesla factory can change the chassis parts in 10 minutes by changing the perforated inserts of different sizes, and improve the efficiency by 40%.

- Surface coating black technology: Spraying diamond-like (DLC) coating on the surface of the mold reduces the friction coefficient of stainless steel sheet metal stamping by 30%, and extends the life of the mold to 500,000 stamping times.

2. "Dynamic balance" of process parameters

- Precise control of holding force: When processing high-strength steel chassis support, the servo hydraulic system is used to adjust the holding force in real time. When the sensor detects abnormal material flow, the pressure value can be adjusted within 0.1 seconds to ±5% to avoid the risk of cracking.

- The art of speed curves: Traditional presses run at a constant speed, which can easily lead to hardening of stainless steel materials. A German brand introduced the "slow-fast-slow" three-stage stamping curve, reducing the speed to 15mm/s in the forming stage, reducing the amount of rebound by 25%.

- Invisible control of temperature field: In the processing of aluminum alloy chassis parts, the cooling pipe is buried inside the mold to stabilize the working temperature at 120±5℃, and the material elongation is increased by 18%.

3. "Offensive and defensive battle" of defect prevention

- Crack warning system: The use of acoustic emission sensors to capture the abnormal acoustic signal of the stamping process can predict the crack generation 3 seconds in advance, and save the annual loss of 3 million yuan for a domestic SUV chassis production line.

- Rebound compensation algorithm: AI-based deformation prediction model, which presets the reverse compensation amount in the mold design stage. For example, an electric vehicle chassis beam is designed with a compensation Angle of 0.7° to compress the assembly error from 1.2mm to 0.3mm.

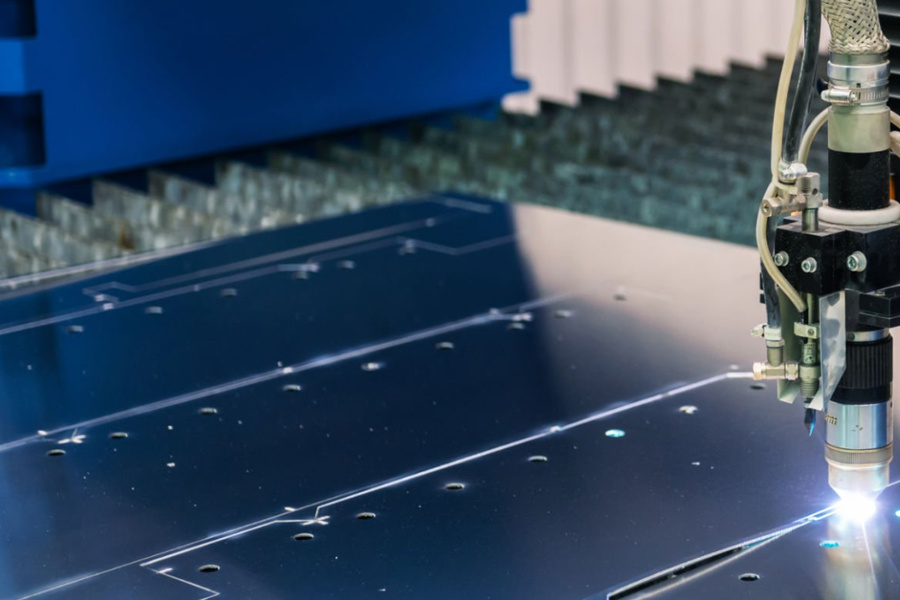

- Oil film control technology: nano-scale lubrication film is sprayed before sheet metal stamping, which not only reduces the scratch of stainless steel surface, but also avoids the contamination of traditional lubricating oil in subsequent welding processes (such as sheet metal laser welding).

Practical breakthroughs from the lab to the production line

Case 1: Stainless steel battery tray stamping

An electric truck manufacturer uses the combination process of "warm stamping + sheet metal laser welding" to press 2.5mm thick stainless steel plate at 380℃ and combine with laser welding reinforcement to increase the strength of parts by 30% and reduce the weight by 15%.

Case 2: Lightweight chassis stringer

Through ultra-high strength steel (1500MPa) hot stamping technology, the thickness of a car chassis longitudinal beam was reduced from 2.0mm to 1.4mm, but the crash test score was improved by 1 star, which confirmed the synergistic effect of stamping process and material science.

Case 3: Flexible production of shaped bracket

Electromagnetic stamping technology is used to change the mold shape in real time by adjusting the magnetic field intensity, realizing the rapid switching of multi-model chassis supports, and reducing the marginal cost of small-batch customized production by 40%.

From steam hammering to intelligent stamping, the evolution of car chassis processing is an epic tale of man's taming of steel. When we use servo motors to replace flywheels and AI algorithms to replace empirical formulas, the cracks, resilience, and efficiency bottlenecks that once plagued the industry are gradually being resolved by technological innovation. Perhaps in the near future, every "steel origami" in the stamping workshop will become an industrial art with a perfect blend of force and beauty.

Key Words