How important is ISO certification to sheet metal processing suppliers

Release time:

2025-03-12

ISO certification is the "quality insurance" for automobile chassis processing. Its three practical values include establishing a replicable quality benchmark, building a problem rapid response network, and achieving cost control. Through ISO certification, enterprises can reduce scrap rates, reduce inspection costs, avoid fines, and achieve a dual improvement in quality, cost, and efficiency.

Why is ISO certification the "quality insurance" of sheet metal processing?

The life and death line of automobile chassis processing: process controllability

As a core load-bearing component, the automobile chassis has extremely high precision requirements for stainless steel sheet metal processing. ISO 9001 certification requires suppliers to establish a complete traceability chain from raw material procurement to finished product delivery:

Material batch management: Each stainless steel plate can be traced back to the steel plant melting furnace number;

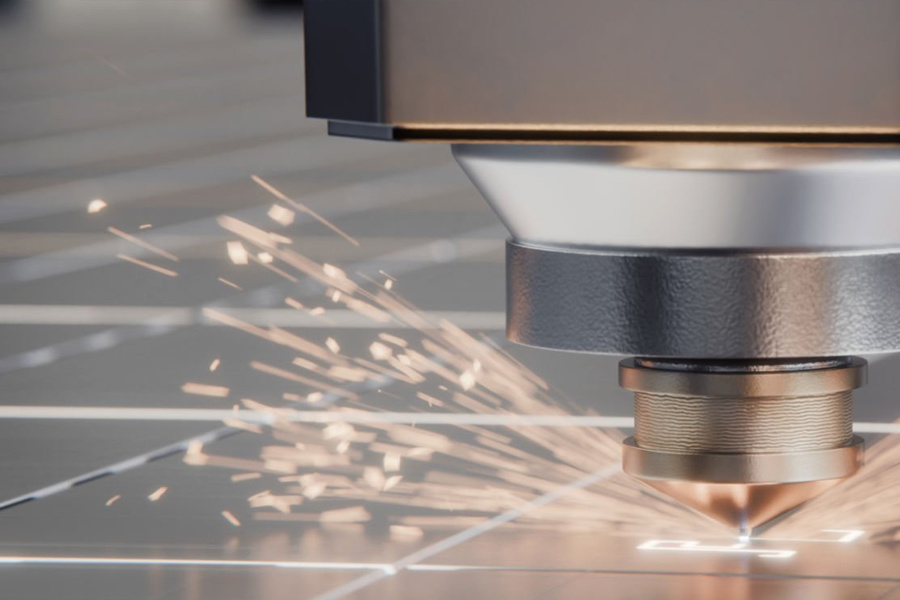

Process parameter solidification: The die pressure of sheet metal stamping and the power fluctuation of laser welding must be controlled within ±2%;

Abnormal response mechanism: When the strength of the sheet metal riveting point is detected to be abnormal, the system automatically triggers a shutdown for troubleshooting.

Data confirms: For companies that have passed ISO certification, the average complaint rate of automobile parts quality is reduced by 63%.

The hidden value of stainless steel sheet metal processing: cost control

ISO certification is not only about quality, but also directly affects the supply chain cost:

Reduce scrap rate: Through statistical process control (SPC), the hole offset defect rate of sheet metal chassis processing is reduced from 5% to 0.8%;

Reduce inspection costs: The size inspection report provided by the certified supplier can be directly accepted by the OEM, eliminating the need for third-party re-inspection;

Avoid the risk of fines: Enterprises that comply with the ISO 14001 environmental management system do not need to worry about order interruptions due to environmental violations.

The three practical values of ISO certification are analyzed

Value 1: Establish a replicable quality benchmark

Take Chuntian Machinery as an example, its three core modules under the ISO 9001 system:

Visualization of work instructions: Each workstation is equipped with a graphic version of the operating specifications to ensure that sheet metal laser welding novices and experienced technicians follow the same standards;

Equipment maintenance calendar: Punch press molds are mandatory for every 5,000 punching to avoid sudden failures leading to batch defects;

Customer customized control: For small batch and multi-variety orders, a separate process parameter database is established (such as the bending compensation coefficient of 1.5mm galvanized sheet is 0.32).

Value 2: Building a rapid response network for problems

In Zhuhai sheet metal bending processing industry, the typical quality processing process of uncertified enterprises takes 72 hours, while the ISO system compresses it to 8 hours:

When the operator finds cracks in the sheet metal riveting point, he immediately scans the code to report the work order;

The quality engineer retrieves the processing parameters of the batch (pressure value, rivet diameter);

The root cause of the problem is unstable air pressure, and 200 products from the same batch are isolated simultaneously;

Value 3: Flywheel effect that drives continuous improvement

ISO certification is not a one-time thing, and its core lies in the PDCA (Plan-Do-Check-Act) cycle:

Monthly quality meeting: Analyze the TOP3 reasons for excessive burrs on sheet metal stamping parts (tool wear, feed speed, material hardness);

Customer feedback closed loop: The "chassis processing grounding plate thickness + 0.1mm" requirement proposed by the automobile OEM will complete process verification and update the standard within 3 days.

Four ISO verification points for purchasing and screening suppliers

Point 1: The real effort behind the certificate

Reject the trap of "buying certificates": require suppliers to provide the latest three internal audit reports and check the rectification records of non-conformities;

Focus of on-site factory inspection: observe whether the "Welding Parameter Comparison Table" is hung at the sheet metal laser welding station and whether the equipment inspection form has daily signatures.

Point 2: Industry adaptability assessment

Automotive industry: give priority to companies that have passed IATF 16949 certification (automotive version of ISO 9001) to ensure that PPAP (production part approval process) requirements are met;

Medical equipment: pay attention to the implementation of the ISO 13485 system, especially the anti-pollution measures for stainless steel sheet metal processing in clean workshops.

Point 3: Verification of flexible production capacity

For small batch order needs, examine the flexibility of the supplier's ISO system:

Quick mold change (SMED): Chuntian Machinery's automobile chassis processing mold change time has been compressed to 18 minutes;

Mixed line production control: When processing sheet metal chassis processing (5mm aluminum plate) and precision electronic housing (0.8mm stainless steel) on the same working day, the color code isolation method is used to prevent mixing.

Point 4: Risk emergency response capability stress test

Simulate emergency scenarios to test the effectiveness of the system:

Sudden material shortage: require suppliers to provide alternative solutions within 24 hours (such as bending compensation adjustment calculations when 304 stainless steel is temporarily replaced by 316L);

Process conflict resolution: When sheet metal riveting and laser welding processes interfere with each other, can the ECN (engineering change notification) process be initiated to coordinate the technical department?

In the field of sheet metal processing, an ISO certificate is not only an official endorsement of the supplier's management capabilities, but also a "moat" for the purchaser to reduce quality risks. Choosing a service provider such as Chuntian Machinery, which has passed multiple certifications and has 20 years of technical accumulation, means obtaining full-process guarantees from automobile chassis processing to precision chassis manufacturing. When price competition turns to value competition, the standardization, transparency, and continuous improvement capabilities built by the ISO system are redefining the entry rules for high-end manufacturing.

Key Words