Sheet metal processing: the coordinated evolution of precision manufacturing and innovative technology

Release time:

2025-04-21

With the advancement of technology, modern sheet metal processing has shifted from manual operation to intelligent manufacturing, using CNC numerical control systems to achieve precise control and shorten product delivery cycles. Application scenarios cover electronic communications, transportation, architectural decoration, medical equipment manufacturing and other fields. When choosing professional services, consider the compatibility of equipment and technology, the degree of process standardization, surface treatment capabilities, etc.

In the field of industrial manufacturing, sheet metal processing is a basic process that supports the production of components from electronic equipment to aerospace equipment. With the in-depth application of automation and digitalization technology, this traditional process is undergoing a transformation and upgrading from manual operation to intelligent manufacturing. This article will analyze the technical value and development direction of modern sheet metal processing based on technical principles, core processes and industry applications.

Technical definition and evolution of sheet metal processing

Sheet metal processing refers to the manufacturing process of converting metal sheets into specific shapes by cutting, bending, stamping and other processes. Traditional processes rely on manual operation of shearing machines, punching machines and other equipment, while modern technology achieves precise control through CNC numerical control systems, and the error range can be controlled within ±0.1mm. This technological upgrade not only improves processing accuracy, but also greatly shortens product delivery cycles through modular design.

Four core technologies of modern sheet metal processing

●Laser cutting technology: Using high-power fiber lasers, it can efficiently complete complex graphic cutting of materials such as stainless steel and aluminum alloys, with smooth incisions and no burrs, reducing subsequent grinding processes.

●CNC stamping: Through programming and control of multi-station molds, batch hole processing and special-shaped structure production are realized, which is especially suitable for standardized products such as chassis and distribution cabinets.

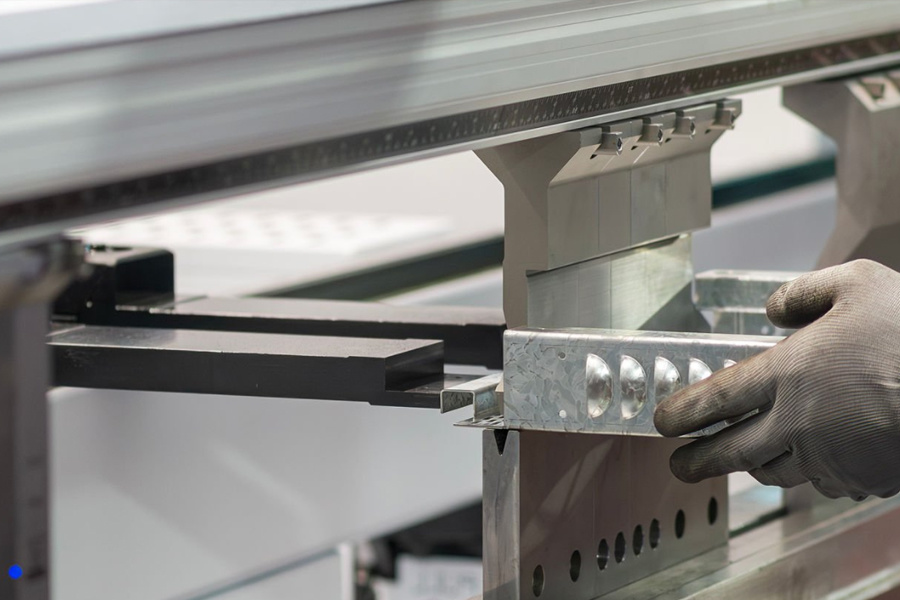

●Precision bending process: The bending machine equipped with a hydraulic servo system can automatically calculate the bending angle according to the material thickness, avoiding the deformation problem caused by traditional manual debugging.

●Automated welding and assembly: The robotic arm welding system cooperates with visual positioning technology to ensure the uniformity of the weld, which is suitable for scenes with high structural strength requirements such as automotive parts.

Industry application scenarios of sheet metal processing

●Electronic communication field: 5G base station housing, server cabinet and other precision component processing

●Transportation industry: new energy vehicle battery tray, rail transit interior parts manufacturing

●Architectural decoration field: curtain wall metal finishing, customized steel structure production

●Medical equipment manufacturing: testing instrument housing, surgical instrument carrier and other sterilization grade material processing

Consideration dimensions for selecting professional sheet metal processing services

●Equipment and technology adaptability: select matching processing equipment according to material thickness (common range of 0.5-6mm)

●Process standardization degree: confirm whether the company has ISO quality management system certification

●Surface treatment capabilities: such as electroplating, spraying =Completeness of secondary processing technology

●Flexible production capacity: Collaborative support for small-batch customization and large-scale batch supply

Industry development trends and technological innovation

●Intelligent production system: Real-time data interaction between MES manufacturing execution system and processing equipment to achieve full-process quality traceability

●Green manufacturing process: Application of low-energy consumption technologies such as water jet cutting to reduce metal dust and waste

●Composite material processing: Research and development of special tools for new materials such as carbon fiber composite panels

●Cloud collaborative design: Customer 3D drawings directly connected to production equipment to shorten the design verification cycle

The leap from traditional manufacturing to intelligent manufacturing in sheet metal processing reflects the continuous pursuit of precision and efficiency in industrial technology. When choosing processing services, companies need to focus on technical adaptability and process integrity rather than simply comparing quotations. With the penetration of Industry 4.0 technology, this field will continue to drive the manufacturing industry to evolve in a high-precision and sustainable direction.

Key Words