Med Sheet Metal Fab: Core Enviro & Process

Release time:

2025-04-23

This article deeply explores the strict requirements of medical sheet metal processing on production environment, material process and quality control, analyzes its core standards in cleanliness, precision and safety, and helps improve the reliability of medical equipment.

In the field of medical equipment manufacturing, sheet metal processing is an important link in supporting the structural function of equipment. Since medical products are directly related to patient safety and treatment effects, their processing must follow specifications that are far higher than ordinary industrial manufacturing. From the production environment to process details, every link must be strictly controlled.

Special requirements for the production environment

● Cleanliness control: Medical sheet metal workshops must meet dust-free standards to avoid metal dust pollution. Especially for products that directly contact medical scenes such as surgical instruments and imaging equipment, an air filtration system must be used to maintain an ISO 7 level or above clean environment to prevent particulate adhesion from affecting equipment performance.

● Temperature and humidity stability: Precision sheet metal parts are sensitive to temperature fluctuations. The processing area must maintain a constant temperature and humidity (usually 22±2℃, humidity 40%-60%) to avoid deformation of materials due to environmental changes and ensure that dimensional accuracy meets the standards.

● Anti-static and anti-corrosion: Medical equipment is mostly used in a disinfected environment. Anti-static facilities must be configured in the processing area to avoid oxidation of the metal surface. For medical materials such as stainless steel, special equipment must be used to reduce the risk of chemical corrosion during processing.

Core standards of process technology

1. Compliance of material selection

Materials that have passed biocompatibility certification, such as 304/316L medical-grade stainless steel and aluminum alloy, should be given priority. Material reports must be verified before raw materials are put into storage to prevent the mixing of non-standard materials.

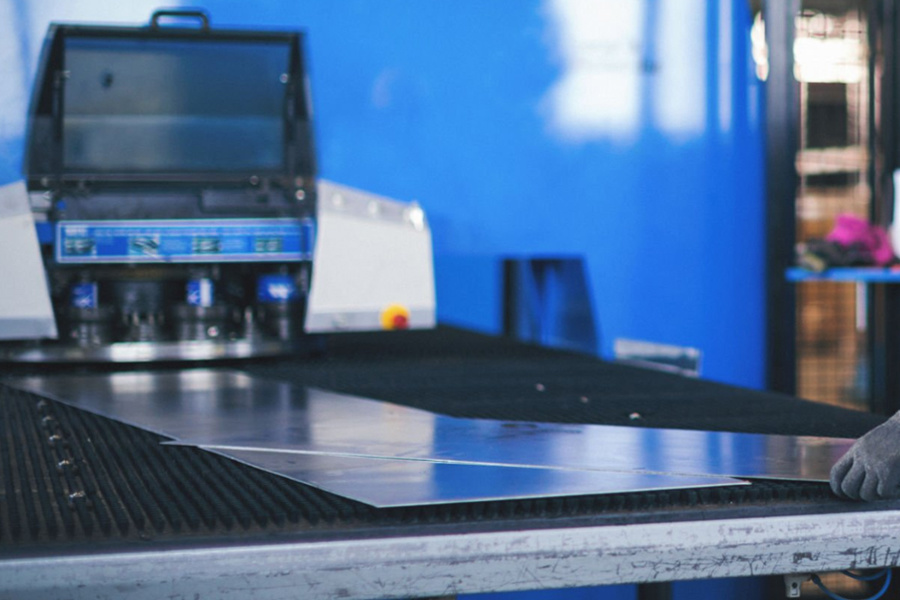

2. Precision processing technology

Laser cutting accuracy: Use fiber laser equipment to ensure that the cut flatness is ≤0.1mm

Bending angle control: Use CNC bending machine with compensation algorithm to achieve ±0.5° error range

Welding process: Argon arc welding/laser welding must meet seamless and traceless requirements to avoid residue affecting cleaning and disinfection

3. Surface treatment specifications

Medical sheet metal parts must be electropolished and passivated to ensure that the surface roughness Ra is ≤0.8μm. Special parts need to be coated with antibacterial coatings to meet the YY/T 0691 medical material surface characteristics standard.

Full process quality control system

● Traceability management: From raw material batches to processing equipment parameters, records and archives are required to achieve product traceability throughout the life cycle. Each batch of products is accompanied by material certification, process parameter records and test reports.

● Non-destructive testing: Use industrial CT scanning, 3D measuring instruments and other equipment to detect hidden structures to avoid secondary damage to precision parts by traditional testing methods.

● Packaging and transportation standards: Finished products must be individually packaged with shockproof and moisture-proof materials, and undergo a 48-hour environmental simulation test before transportation to ensure that the delivered products are free of oxidation and deformation.

Medical sheet metal processing is a technology-intensive link in the medical equipment manufacturing chain. Its stringent environmental and process requirements directly determine the safety and reliability of the final product. Only by choosing a processing service provider with professional qualifications and a complete quality system can we provide long-lasting and stable hardware support for medical equipment.

Key Words