Sheet Metal Fabrication Guide: From Process Advantages to Industry Applications

Release time:

2025-05-15

Sheet metal processing plays a key role in industrial manufacturing. Through full-process process collaboration and precise molding, it ensures the airtightness and scratch resistance of medical device shells. The combination of automation and manual experience gives sheet metal processing advantages in efficiency and personalized customization.

In today's huge industrial manufacturing system, sheet metal processing is not only a key support link for precision equipment such as inkjet printers and industrial inkjet printers, but also a key support for the safety and structural balance of medical equipment shells. This article will analyze how sheet metal processing has become an important cornerstone of industrial manufacturing from the aspects of technical characteristics, main uses, quality management and service methods, and the core elements that enterprises should pay attention to when choosing processing services.

Sheet metal processing: multi-dimensional shaping method of metal materials

Sheet metal processing is not just cutting and bending, but a series of precision processes to transform flat metal materials into three-dimensional components that meet design requirements. Its core value is as follows:

1. Collaborative innovation in the whole process

From the mm precision control of laser cutting to the precise forming of CNC bending, and then to the corrosion resistance of surface spraying, each process should be a deep combination of technology and experience. For example, in the processing of medical device shells, the airtightness of the shell should be ensured by several bends, and the surface edges should be removed by polishing to avoid the risk of scratches that may occur in traditional processing.

2. Flexible and convenient solutions for suitable materials

The technical performance of metal parts in different fields is obviously different: inkjet printer parts must be lightweight aluminum alloys with excellent conductivity, while industrial inkjet printer sheet metal focuses on the high wear resistance and shock resistance of stainless steel plates, and medical equipment shells pay more attention to special treatment of antibacterial and compatibility. Complete sheet metal processing companies can formulate process plans based on material characteristics to ensure that components operate efficiently in specific scenarios.

3. Win-win cooperation between automation and human experience

Today's sheet metal processing uses facilities such as automatic CNC punching machines and robot welding to improve efficiency, but key steps also require human experience intervention. For example, the establishment of complex surfaces requires technicians to adjust mold parameters based on the rebound characteristics of the plate. The combination of "equipment precision and artificial intelligence" not only ensures the stability of mass production, but also provides the possibility of personalized customization.

Code for sheet metal application in cross-domain scenarios

The value of sheet metal processing shows distinct industry characteristics in different fields:

In the field of intelligent printing equipment: clear precision and characteristic limitations

The processing of key components of inkjet printers is very strict to standard tolerances. For example, the positioning hole deviation of the nozzle bracket should be kept within 0.1mm during this period, otherwise it may cause printing errors or ink breakage. According to the bending and forming of sheet metal processing and surface electroplating, the wear resistance and conductivity of parts can be comprehensively improved to ensure the stability of long-term high-frequency use of equipment.

Industrial inkjet printer manufacturing: durability is the core demand

The dust, vibration and temperature difference changes in industrial environments require the sheet metal structure of inkjet printers to have excellent maintenance characteristics. In the processing link, the impact resistance should be improved through the design of structural columns, the dust and water resistance level should be improved by selecting rubber strip slot technology, the layout of heat dissipation holes should be improved to avoid overheating of internal components, and ensure the continuous operation of the system in harsh environments.

Precision machining of medical machinery: multiple considerations of safety and function

The housing of medical equipment should not only comply with regulations, but also comply with the ISO 13485 quality system standard. Attention should be paid to ergonomic design. For example, the arc connection of the surgical equipment shell can prevent accidental scratches during operation. The surface anodizing process not only improves the aesthetics, but also imparts antibacterial properties. The electromagnetic shielding design of the internal circuit board bracket needs to effectively isolate signal interference based on precision bending and welding processes.

Quality Management: Building Hidden Competitiveness of Sheet Metal Processing

For the manufacturing industry that relies on the reliability of components, stable quality export is the key basis for selecting processing service providers:

1. Establish a full-chain inspection system

From the spectral analysis of raw materials entering the warehouse, to the calibration of the coordinate measuring instrument after molding, and then from the salt spray test after surface treatment, each link must generate a complex quality file. Especially in the diagnosis and treatment of precision sheet metal processing, it is necessary to pay attention to the appearance roughness detection and compatibility evaluation to ensure that the parts touching the body meet the medical testing standards.

2. Continuous optimization mechanism of error control

According to the PDCA cycle (plan-implementation-inspection-solution), the common bending rebound, welding deformation and other problems in processing are analyzed, and the error rate is gradually reduced through mold improvement or process index adjustment. This pursuit of "zero defect" quality culture is the key support for the company's long-term service to high-end customers.

3. The ability to balance standardization and customization

On the premise of following GB/T 15055 and the government's standard tolerance specifications for sheet metal processing, flexible solutions are provided for customers' special requirements (such as unique thread hole locations and personalized surface textures). For example, parts processed for overseas customers should comply with local safety regulations, and complete processing companies can quickly respond to the access requirements of different markets through process adjustments.

Service upgrades in global layout: innovation and manufacturing with experience

Sheet metal processing companies that have been deeply involved in the industry for 20 years generally have more mature technical accumulation and guarantee mechanisms:

1. Advantages of cross-regional capacity allocation

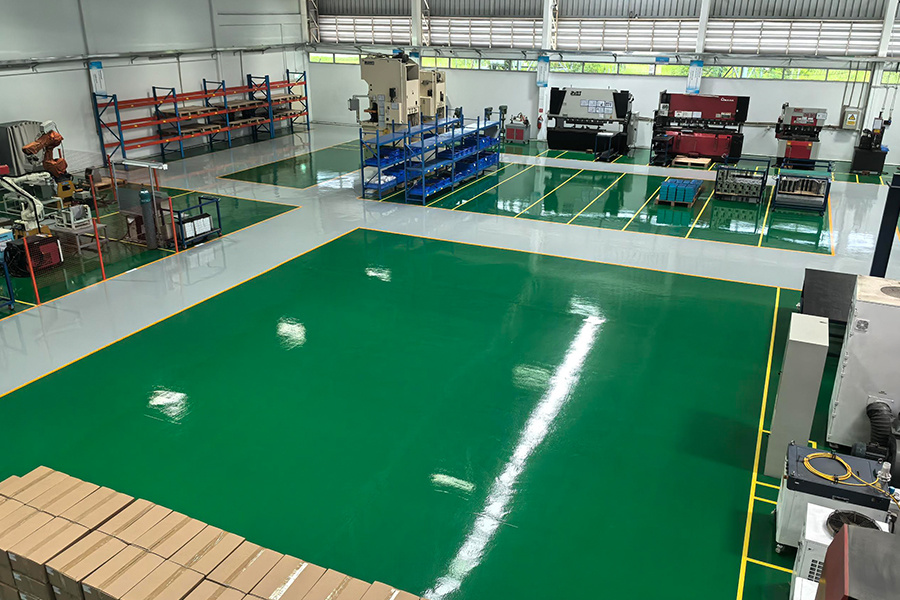

Establishing factories in international markets such as Thailand and Malaysia can not only be close to Southeast Asian manufacturing clusters and reduce supply chain cycles, but also flexibly adjust production plans according to material characteristics and process specifications in different regions, and provide localized supporting plans for multinational companies.

2. From processing to collaborative value extension

High-end processing companies will check the interference drawings of the previous work and make optimization suggestions from the perspective of process feasibility, such as simplifying the multi-component splicing structure into an integrated forming to reduce assembly errors and expenses. This kind of "technical experience" early intervention can prevent hidden design defects for customers.

3. Seamless connection between small-batch trial production and mass production

For areas with high reliability requirements for medical machinery, small-batch trial production services are provided, and feedback is collected through actual storage inspections, and measures are improved to ensure the stability of mass production. At the same time, relying on automatic assembly lines, different order sizes can be properly handled while ensuring accuracy.

Conclusion Summary As a "precision supporting hub" for industrial manufacturing, the value of sheet metal processing has long exceeded a single processing service and has become an important factor in promoting equipment updates. Whether it is high-precision parts for intelligent printing equipment or safety housings for medical equipment, the deep integration of production processes and industry needs is indispensable. For enterprises, choosing a processing service provider with many years of experience and a global layout can not only obtain stable quality assurance, but also improve product design and overall competitiveness through technical collaboration. As the manufacturing industry moves towards specialization and globalization, sheet metal processing will continue to bring innovative development in more fields with its process precision and service depth.

Key Words