Sheet metal processing: the invisible backbone of modern industry

Release time:

2025-06-03

In the manufacturing industry, sheet metal processing is the basic support for many industries. Its process can adapt to small batch customization and large-scale manufacturing needs through rapid conversion of CNC technology. The cost-effectiveness is significantly reduced, and integrated manufacturing realizes the integration of the entire process of the industrial chain. Driven by innovation, it has become the forefront of China's intelligent manufacturing.

In the vast system of manufacturing, sheet metal processing is like a silent cornerstone, supporting countless industries from precision electronics to heavy machinery. The importance of this manufacturing process that shapes, cuts and connects metal sheets is becoming increasingly prominent with industrial upgrading.

Basic support role

Sheet metal processing is the underlying technical language of industrial manufacturing. From equipment housings to core components, more than 70% of industrial products contain sheet metal components. The ability of this process to transform flat metal into three-dimensional structures achieves the unity of product functionality, protection and aesthetics. Whether it is the shielding cover of microelectronic equipment or the protective cabin of energy equipment, it relies on precise sheet metal forming technology.

Key manufacturing advantages

1. Flexible production capacity

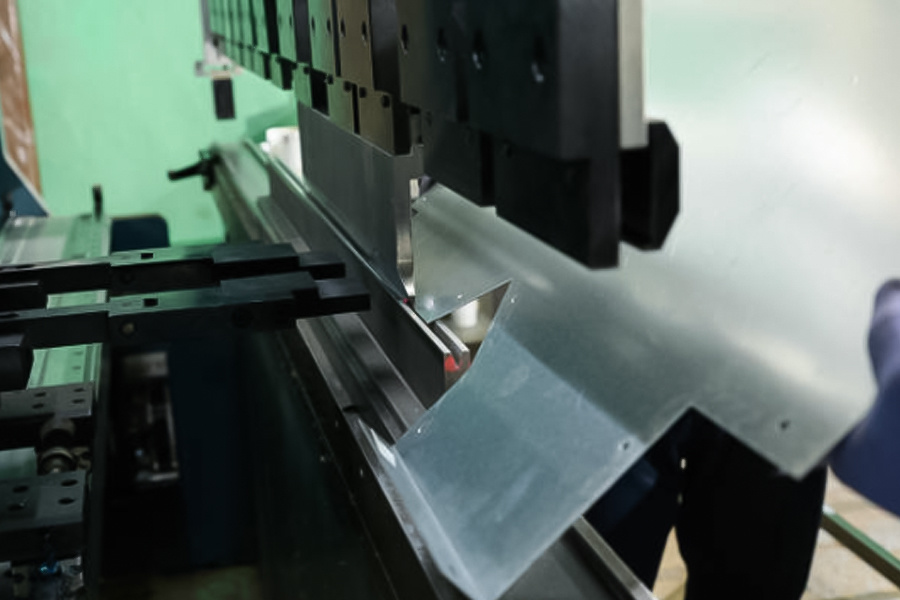

Unlike mold production, sheet metal processing can achieve rapid production conversion through CNC technology, and can flexibly adapt to small-batch customization and large-scale manufacturing needs

2. Cost-effectiveness ratio

On the premise of ensuring structural strength, sheet metal parts can significantly reduce manufacturing costs by optimizing material utilization

3. Integrated manufacturing

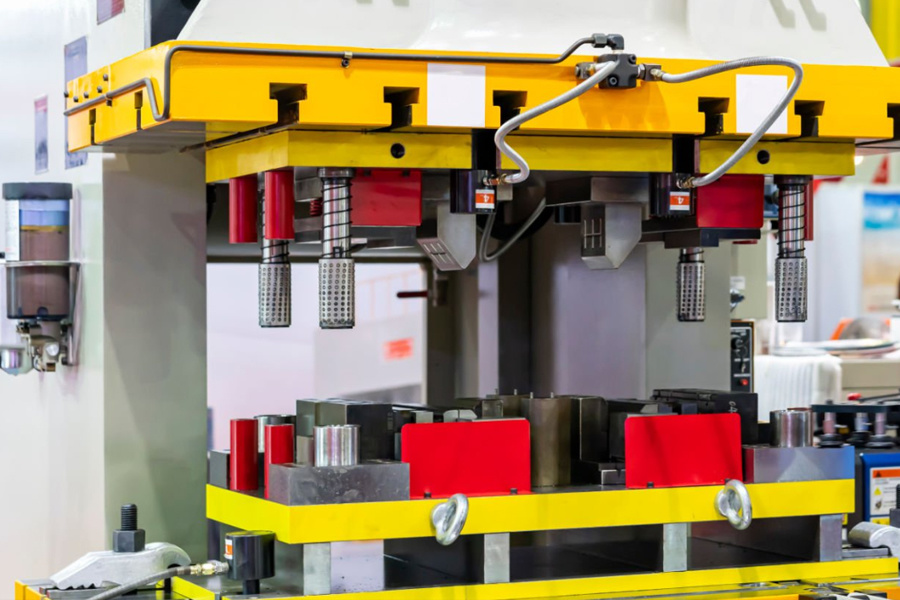

Modern sheet metal processing integrates laser cutting, precision bending and other processes to achieve full process integration from raw materials to finished products

Core link of the industrial chain

Sheet metal processing is a key link between the upper and lower levels:

● Upstream connection with material science progress (such as new alloy applications)

● Downstream support for equipment manufacturing upgrades (such as new energy equipment structure optimization)

● This bridge role makes it a key carrier for the implementation of industrial innovation.

Frontier position of technological innovation

With the advancement of intelligent manufacturing, sheet metal processing is undergoing a triple evolution:

● Digitalization: CAD/CAM system realizes design and manufacturing integration

● Precision: Micron-level tolerance control improves product reliability

● Green: Flexible production reduces material waste

Thuntian Machinery, which has been deeply involved in the industry for 20 years, has built a complete industrial system covering design, manufacturing and testing. By continuously promoting technological upgrades and capacity optimization, and establishing a professional production base in Thailand, we are exporting mature sheet metal solutions to the world and providing highly consistent manufacturing services to international customers.

Key Words