Application scope and technical points of broaching

Release time:

2024-10-29

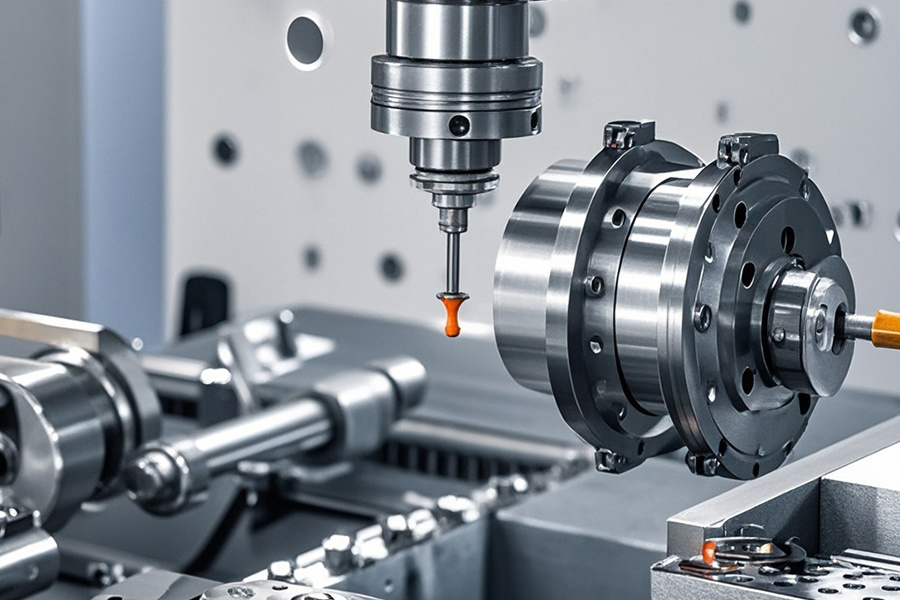

Broaching is a processing method that uses a broach to cut on a workpiece. The broach has multiple teeth. By cutting the workpiece in sequence, it can complete the processing of complex shapes in one pass, thereby greatly improving the processing efficiency and accuracy.

Broaching is a processing method that uses a broach to cut on a workpiece. The broach has multiple teeth. By cutting the workpiece in sequence, it can complete the processing of complex shapes in one pass, thereby greatly improving the processing efficiency and accuracy.

In the automotive field, broaching plays an important role. Many key components in automobile engines, such as gears, spline shafts, etc., often require high-precision processing. Zhuhai Chuntian Machinery Technology Co., Ltd. has made full use of broaching technology in the manufacture of automotive parts. Through carefully designed broaches and precise control of processing parameters, automotive parts with high precision and high surface quality can be manufactured, providing a strong guarantee for the performance and reliability of the car. For example, in the broaching of gears, the tooth shape and size of the broach can accurately control the modulus, number of teeth and tooth shape accuracy of the gear, ensuring the stability and accuracy of the gear during the transmission process.

The development of intelligent industry has brought new opportunities and challenges to broaching. In smart factories, broaching equipment can be networked and coordinated with other smart devices to achieve automated production and intelligent management. Through real-time monitoring and feedback from sensors and control systems, the cutting force, temperature, tool wear and other parameters in the broaching process can be precisely controlled, thereby improving the processing quality and stability. At the same time, the intelligent industry can also use big data and artificial intelligence technology to optimize and predict the broaching process, discover potential problems in advance and take corresponding measures to further improve production efficiency and reduce costs.

In the field of life sciences, broaching also has certain applications. Precision parts in some medical equipment and instruments, such as micro gears and threaded parts, require high-precision processing methods. Broaching, with its ability to process complex shapes and high precision, provides support for the development of the life science field. For example, in the manufacture of some minimally invasive surgical instruments, broaching can produce parts with tiny sizes and high precision, meeting the requirements of minimally invasive surgery for instrument accuracy and reliability.

The technical points of broaching mainly include the following aspects:

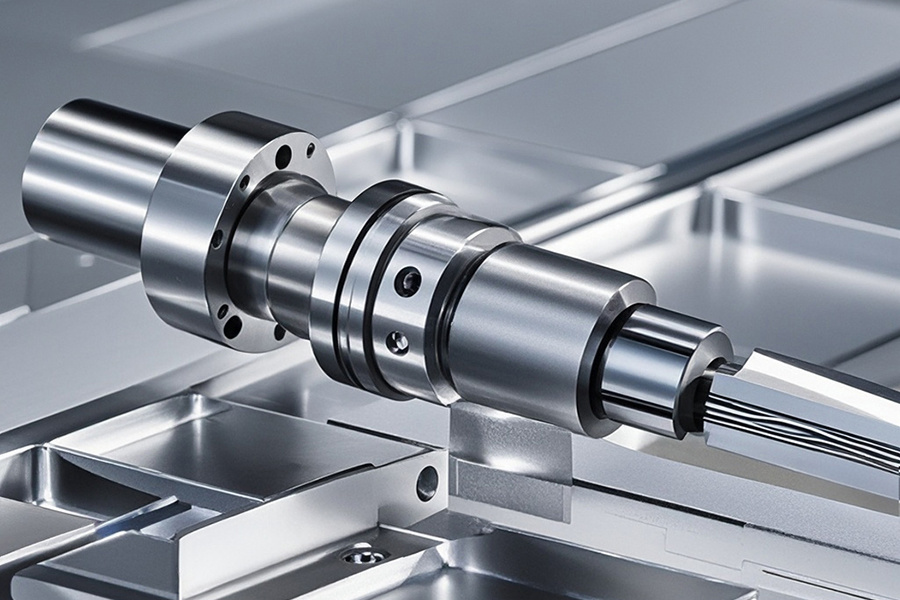

1. Design and manufacture of broaches: The design of broaches needs to be carefully planned according to the shape, size and processing requirements of the workpiece. Factors such as the tooth shape, tooth pitch, and tool material of the broach will directly affect the processing quality and efficiency. During the manufacturing process, high-precision processing equipment and advanced manufacturing processes are required to ensure the dimensional accuracy and surface quality of the broach. At the same time, in order to improve the service life and processing efficiency of the broach, coating technology and optimized tool geometry can also be used.

2. Selection of broaching parameters: Broaching parameters include broaching speed, feed rate, cutting depth, etc. The selection of these parameters needs to be comprehensively considered based on the workpiece material, broach performance and processing requirements. Generally speaking, for workpiece materials with higher hardness, lower broaching speeds and smaller feed rates need to be selected to prevent the tool from wearing too quickly; while for materials with lower hardness, the broaching speed and feed rate can be appropriately increased to improve processing efficiency.

3. Clamping and positioning of the workpiece: In the broaching process, the clamping and positioning of the workpiece must be firm and reliable to prevent the workpiece from being displaced or vibrated during the processing, affecting the processing accuracy. At the same time, the positioning accuracy of the workpiece is also directly related to the processing quality, so high-precision positioning devices and detection methods are required to ensure that the positioning of the workpiece is accurate.

4. Quality inspection and tool maintenance after broaching: The workpiece after broaching needs to undergo strict quality inspection, including dimensional accuracy, surface roughness, shape accuracy and other aspects. For workpieces that do not meet the requirements, timely adjustment and repair are required. At the same time, the broach will gradually wear out during use, so it needs to be maintained and replaced regularly to ensure the processing quality and efficiency.

In short, broaching, as a type of intelligent mechanical processing, has broad application prospects in the automotive field, intelligent industry, life sciences and other fields. By continuously optimizing the broach design, selecting appropriate processing parameters, improving the workpiece clamping and positioning accuracy, and strengthening quality inspection and tool maintenance, the quality and efficiency of broaching can be further improved, making greater contributions to the development of the manufacturing industry.

Key Words