Sheet metal assembly process: the key to a stable structure

Release time:

2024-12-06

The metal sheet assembly process is crucial. There are many factors affecting stability, such as welding and riveting. The future is towards automation, intelligence, and green development. Improve quality, provide reliable support for modern industry, and start a new journey of metal sheet assembly.

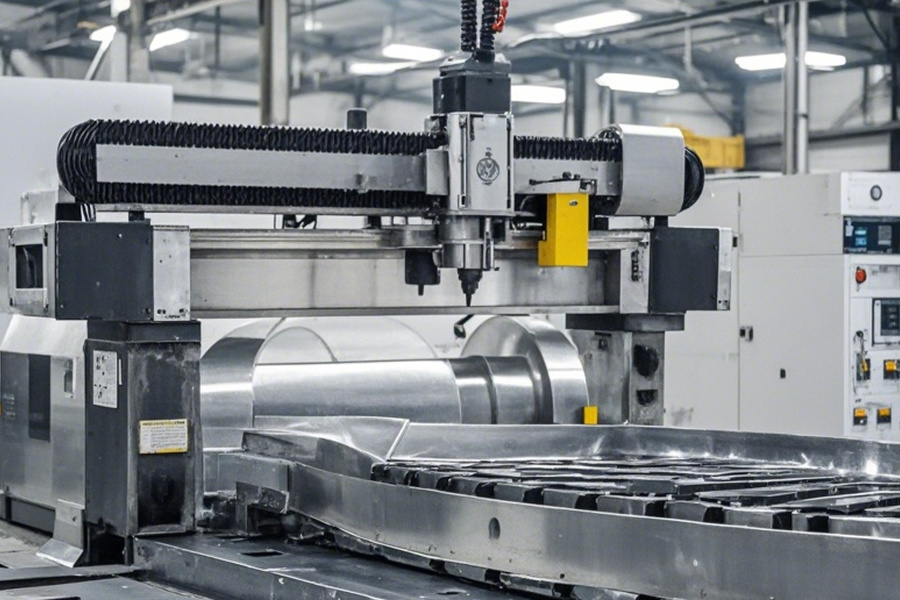

In modern industrial production, sheet metal is widely used because of its lightness, high strength and strong plasticity. However, to assemble these sheet metal into a stable structure, a series of sophisticated processes and technologies are required. The sheet metal assembly process is the key link to ensure the stability of the structure.

Sheet metal is often difficult to meet the structural requirements in practical applications in a single state. Through the assembly process, multiple sheet metal sheets can be connected together to form larger and more complex structures to meet different industrial fields and product requirements. For example, in automobile manufacturing, most of the parts of the car body are composed of sheet metal. Through precise assembly processes, the strength and stability of the car body are ensured to provide safety for passengers. In the manufacture of electronic equipment housings, the assembly process of sheet metal can ensure the sealing and impact resistance of the housing and protect the internal electronic components.

Common sheet metal assembly processes

- Welding: Welding is a process of fusing sheet metal together by heating or pressurizing. Common welding methods include arc welding, gas shielded welding, laser welding, etc. The advantages of welding are high connection strength, good sealing, and permanent connection. However, high temperatures are generated during welding, which may cause deformation of the metal sheet and require subsequent correction. In addition, welding has high technical requirements for operators and requires professional training.

- Riveting: Riveting is a process of connecting metal sheets together by rivets. The advantages of riveting are simple operation, low cost, and can be assembled on site. Moreover, riveting does not generate high temperatures and has little effect on the deformation of metal sheets. However, the connection strength of riveting is relatively low, and the sealing is not as good as welding. In some occasions where the connection strength is not required, such as ventilation ducts, shelves, etc., riveting is a commonly used assembly process.

- Bolting: Bolting is a process of fixing metal sheets together using bolts and nuts. The advantages of bolting are easy disassembly, maintenance and replacement of parts. At the same time, bolting can control the strength of the connection by adjusting the preload of the bolts. However, bolting requires drilling holes in the metal sheet, which will weaken the strength of the metal sheet. In addition, the appearance of bolting is not as beautiful as welding and riveting.

Factors affecting the stability of metal sheet assembly

- Material selection: There are many types of materials for metal sheets, and different materials have different mechanical properties and welding properties. When selecting materials, it is necessary to consider factors such as the use environment and load-bearing requirements of the structure and select suitable metal sheet materials. For example, in situations where high strength is required, high-strength alloy steel can be selected; in situations where corrosion resistance is required, stainless steel can be selected.

- Connection process parameters: Different assembly processes have different process parameters, such as welding current, welding speed, rivet diameter, bolt preload, etc. These process parameters directly affect the quality and stability of the connection. In actual production, it is necessary to reasonably select process parameters and strictly control them according to factors such as the material, thickness, and structural form of the metal sheet.

- Surface treatment: Surface treatment of metal sheets can improve the stability and corrosion resistance of the connection. Common surface treatment methods include sandblasting, phosphating, and galvanizing. Sandblasting can remove oxide scale and impurities on the surface of metal sheets and improve the quality of welding and riveting. Phosphating can form a phosphating film on the surface of metal sheets to improve the adhesion and corrosion resistance of the coating. Galvanizing can form a zinc layer on the surface of metal sheets to prevent metal sheets from rusting.

The metal sheet assembly process is a key link in stabilizing the structure. The stability and quality of metal sheet assembly can be improved by selecting appropriate assembly processes, controlling process parameters, and performing surface treatment. In the future, with the continuous advancement of science and technology, metal sheet assembly processes will continue to innovate and develop, providing more reliable technical support for modern industrial production.

Key Words