Processing capacity

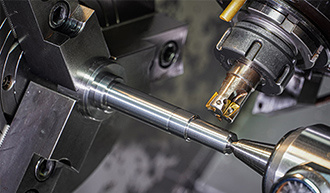

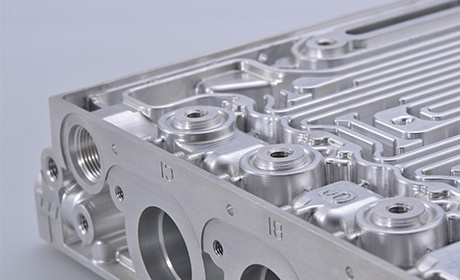

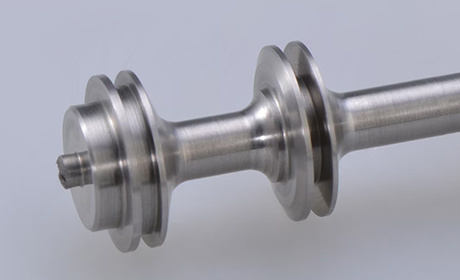

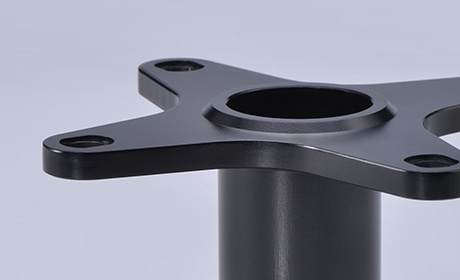

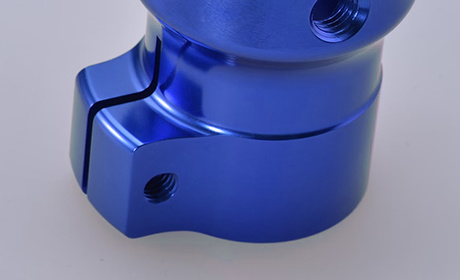

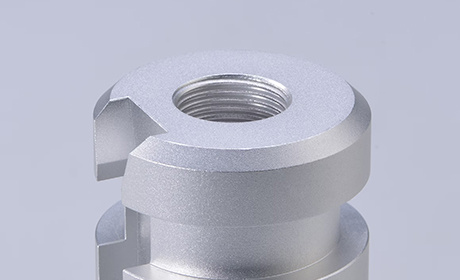

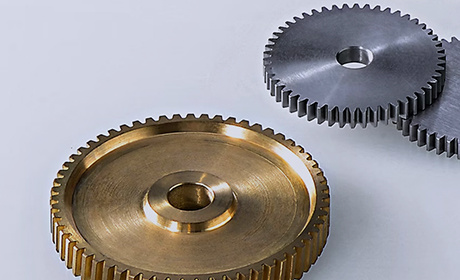

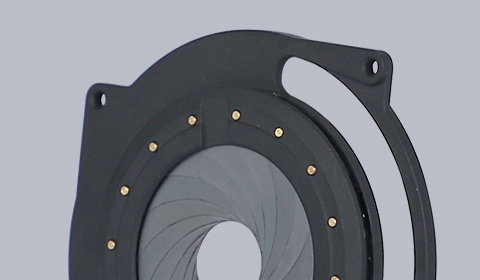

CNC Machining

- Mill-turn Composite Machining Center、Standard 3-Axis、Continuous 5-Axis、3+2 Axis Milling Machine、Drilling and Post-Processing

- More than 50 types of materials and over 12 surface treatments;

- Automatic Tool Changer (ATC) and a tool magazine capacity of over 300 tools

Sheet Metal Processing

- Laser, Plasma jet cutting, Hole Machining, Bending, Stretch Forming,, Metal spinning

- 40T-750T stamping equipment

- AGV, MIG and TIG welding

Rapid Tooling

- Computer-Aided Engineering(CAE)、Design for Manufacturing(DFM)、

- Stack Mold、2K Injection Molding、Hot and Cold Die Casting

- Automated production of 40T-750T complex die castings,Long service life: 1 million times,Hardness: 30-60HR

3D Printing

- FDM、SLS、MJF、SLA、SLM

- Materials: Choose from 35 types of materials (rigid and flexible plastics, elastomers, metals, etc.)

- Surface treatment: Dyeing, Media tumbling, Sandpaper grinding, etc.

Surface treatment method

Machining

The surface of the part leaves a trace of the tool path and does not need to be polished.

Wire drawing

A line-like texture is formed by scraping the metal surface by the abrasive material.

Spraying

The paint is evenly sprayed on the metal surface through the spray gun to form a protective film.

Sand blasting

Use high-speed jet of sand to impact the metal surface to remove dirt, oxide layer and burrs.

passivation

Chemical methods are used to form a dense oxide film on the metal surface to improve corrosion resistance.

Painting

The coating is applied to the metal surface to form a uniform coating with both decorative and protective effects.

Nickel plating

A nickel coating is deposited on the metal surface by electroplating or electroless plating to improve corrosion resistance and appearance.

electrolytic polishing

The principle of electrolysis is used to form a bright polishing layer on the metal surface to increase the surface finish.

Anti-hand fingerprint

Use special coatings or treatments to reduce the possibility of fingerprints on metal surfaces.

QPQ

A composite surface treatment technology, including quenching, polishing and nitriding processes, to improve wear resistance and corrosion resistance.

electrophoresis

The coating is deposited on the metal surface by electrophoresis to form a uniform and dense coating.

Gold Plated

Gold is deposited on the metal surface by electroplating or electroless plating to improve decoration and conductivity.

Dacromet

A zinc-chromium coating technology that forms a highly corrosion-resistant coating by applying a zinc-chromium paint.

ceramic oil

The ceramic particles are mixed with lubricating oil and coated on the metal surface to provide wear resistance and lubricating properties.

Materials we provide

CNC Machining Metal

CNC Machining Plastics

3D printing plastic

Plastic injection molding

sheet metal

Industries served

Equipment innovation for the study of life phenomena, biological processes and medical devices to improve human health

Provide high-precision machining and custom design to promote the development of medical technology

Customize efficient automation equipment to enhance durability and optimize cost-effectiveness

Design and manufacture various mechanical equipment and parts to realize industrial production automation

Providing precision metalworking for the aerospace sector to support the dream of exploring the universe

Service industry

Manufacture of automotive chassis systems and related parts for transportation needs

Equipment innovation for the study of life phenomena, biological processes and medical devices to improve human health

Provide high-precision machining and custom design to promote the development of medical technology

Customize efficient automation equipment to enhance durability and optimize cost-effectiveness

Design and manufacture various mechanical equipment and parts to realize industrial production automation

Providing precision metalworking for the aerospace sector to support the dream of exploring the universe

Let's Start A New Project Today

Get Quote