CTT & ADL: Custom-grade automotive fenders for perfect protection

Release time:

2024-12-30

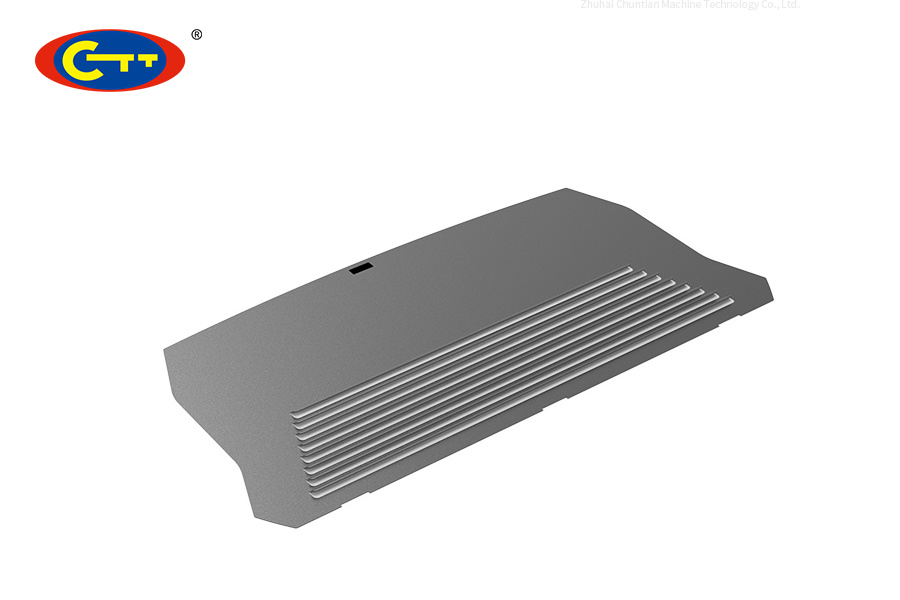

Car skins are related to the beauty, safety and durability of cars. Chuntian Technology cooperates with ADL, adopts digital manufacturing processes, uses advanced technologies such as laser cutting, is equipped with professional workshops and numerous equipment, and can undertake various types of customized processing to ensure that the skin fits perfectly with the car body with high precision to meet the diverse needs of car manufacturing and modification.

In the field of automobile manufacturing and modification, automobile skin, as an important part of the car body, is not only related to the aesthetics of the vehicle, but also directly affects its safety and durability. So, how did the name of automobile skin come about? In what parts and scenarios is it mainly used?

Automobile skin, as the name suggests, is a protective shell covering the surface of the car body, which mainly plays the role of decoration, protection and sound insulation. It is widely used in key parts such as the hood, roof, door, trunk lid, etc. of the car, and is the key to improving the overall texture and protective performance of the car.

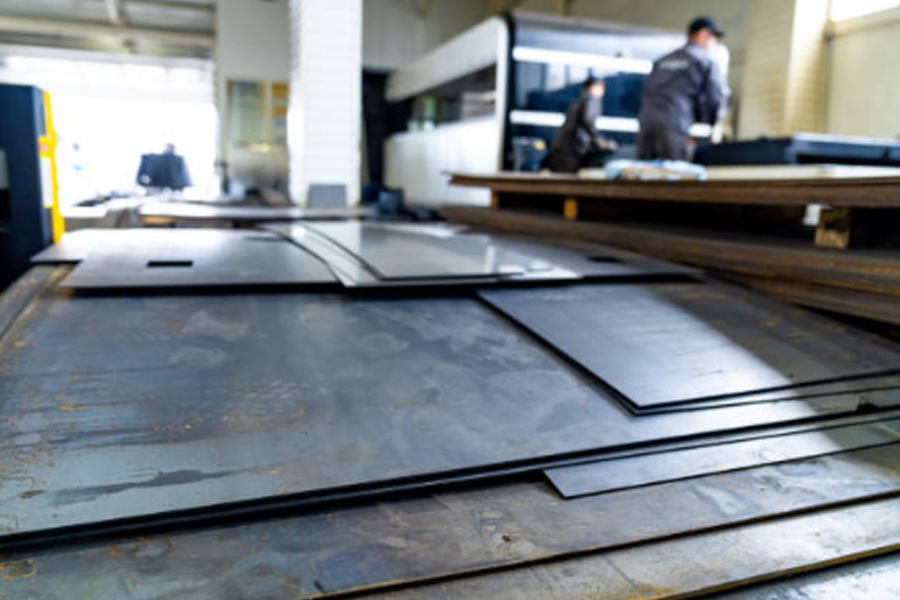

Chuntian Technology, which has been deeply involved in the field of automobile product manufacturing for many years, has worked with ADL to jointly create a number of customized automobile skins, which have won unanimous praise from customers for their excellent quality and exquisite craftsmanship. From material selection to process optimization design, we use advanced digital manufacturing processes to ensure that each piece of skin can fit perfectly with the car body and the error is controlled within a very small range. In terms of processing technology, we use advanced technologies such as laser cutting, CNC bending and precision welding to ensure that the skin maintains a high degree of accuracy and stability during processing.

In order to meet the diverse needs of customers, Chuntian has specially designed a manufacturing workshop for automotive skins, equipped with hundreds of advanced equipment, such as CNC stamping, automatic loading and unloading, laser cutting, automatic painting, automatic welding fixtures and other hardware equipment. Professional automated production lines, standardized production process standards, and strict lean production models enable us to undertake customized processing services ranging from small batches of multiple varieties to large batches of high-precision products.

Key Words