Key points in the design and maintenance of molds in sheet metal processing

Release time:

2025-02-21

In inkjet printer parts processing, the key is to select high-quality mold steel and reasonably design the demoulding mechanism. Cleaning, maintenance and regular inspection of the mold are important links to ensure processing accuracy. At the same time, ensure that the storage environment of the mold is dry and ventilated to avoid moisture and rust.

In the field of sheet metal processing, sheet metal molds play a vital role, which directly affects the quality, production efficiency and processing cost of products. Especially in scenarios such as inkjet printer parts processing that require high precision, high-quality sheet metal molds and scientific maintenance are essential. Next, let's discuss the design and maintenance points of sheet metal molds.

Design points of sheet metal molds

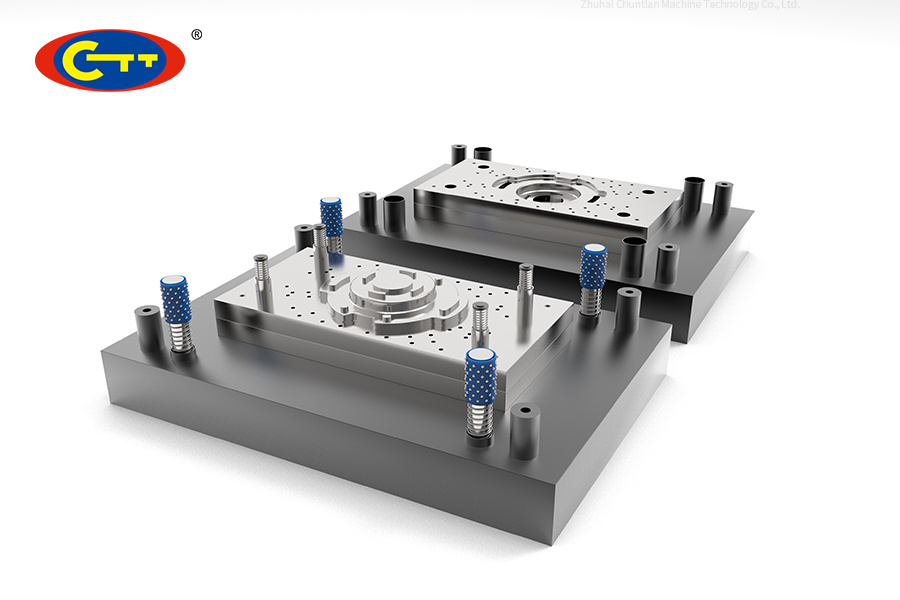

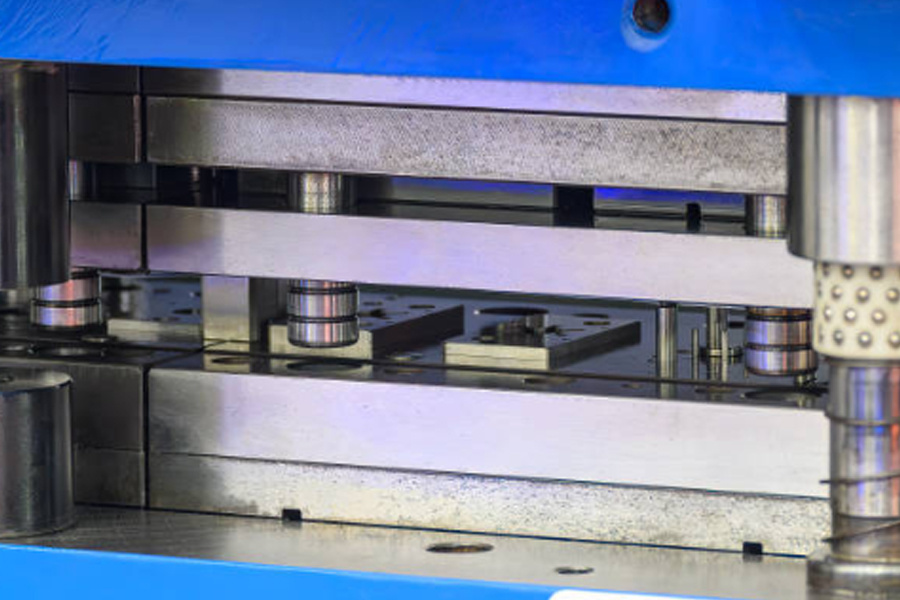

- Reasonable structural design: When designing sheet metal molds for inkjet printer parts processing, the shape and size of the parts should be fully considered. For example, the shell of the inkjet printer usually has complex curves and precise hole requirements. The structure of the mold must ensure that these shapes can be accurately stamped and bent, and at the same time, the stability of the mold during the working process must be ensured to avoid deformation or damage caused by unreasonable structure. Reasonable design of the demoulding mechanism facilitates the smooth demoulding of the processed parts and reduces damage during the demoulding process.

- Material selection: The material of the sheet metal mold determines the durability and processing accuracy of the mold. For inkjet printer parts processing, due to the high precision and large batch size of the parts, mold steel with high hardness and good wear resistance should be selected. Such materials can withstand long-term stamping, shearing and other processing actions, reduce mold wear, ensure long-term stable processing accuracy, and reduce product defective rate caused by mold wear.

- Consider processing technology: When designing molds, actual sheet metal processing technology, such as stamping, bending, stretching, etc., should be combined. For example, in the bending processing of inkjet printer parts, the design of the mold should accurately calculate the bending angle and rebound amount, so that the bent parts meet the design requirements, and avoid multiple corrections due to design and process inconsistency, wasting time and materials.

Main points for sheet metal mold maintenance

- Regular cleaning: Clean the sheet metal mold after each use. During the processing of inkjet printer parts, metal debris, oil and other impurities will remain on the mold surface. If they are not cleaned in time, the mold will be worn faster and the processing accuracy will be affected. Use special cleaning agents and tools to carefully remove impurities on the surface and inside of the mold to keep the mold clean.

- Inspection and maintenance: Regularly conduct a comprehensive inspection of the mold to check whether there are loose parts, wear, deformation, etc. For the inkjet printer parts processing mold, focus on checking key parts, such as punches, dies, etc. If problems are found, repair or replace parts in time, and lubricate and maintain the moving parts of the mold to ensure the normal operation of the mold.

- Correct storage: When the mold is not in use temporarily, it should be properly stored. Place the mold in a dry and ventilated environment to avoid moisture and rust. For the inkjet printer parts processing mold, anti-rust paper can be used to wrap it to prevent oxidation of the mold surface and extend the service life of the mold.

In sheet metal processing, whether it is inkjet printer parts processing or the production of other sheet metal products, the design and maintenance of sheet metal molds cannot be ignored. Reasonable design can improve processing efficiency and product quality, and scientific maintenance can extend the service life of the mold and reduce production costs. If you want to know more about other technical points of sheet metal processing in the future, please feel free to ask me questions.

Key Words