What is the difference between CNC and sheet metal?

Release time:

2024-12-19

CNC and sheet metal have their own advantages in the processing field. CNC processing has a wide range of objects and high precision, while sheet metal processing focuses on thin plate forming. Zhuhai Chuntian Machinery has deeply studied the differences between the two processes. With advanced equipment and professional teams, it has been accurately applied in multiple industries such as aviation and electronics, either to make precision parts or to make sheet metal components, promoting processing technology innovation and application expansion.

In the vast world of mechanical processing, CNC processing and sheet metal processing are two common and important process methods, and there are many significant differences between them.

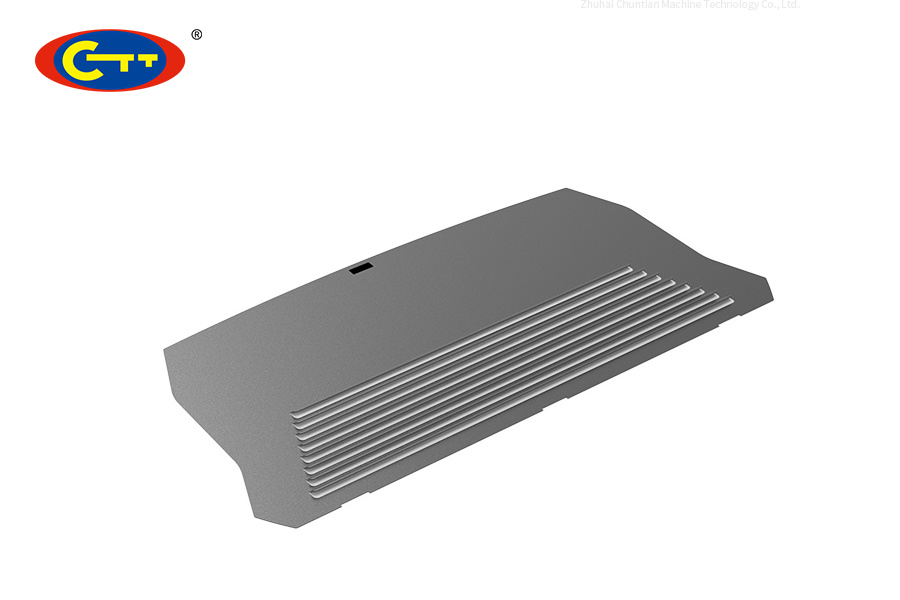

From the perspective of processing objects, CNC processing objects are more extensive. It can process various metal and non-metal materials, such as steel, aluminum, plastic, wood, etc., and can produce parts with complex shapes and extremely high precision requirements. Whether it is a mechanical part with a fine internal structure or a sculpture model with a unique shape, CNC can transform the design into a physical object with its precise digital control capabilities. Sheet metal processing is mainly for metal sheet materials, usually metal sheets with a thickness of less than 6 mm, and common ones are cold-rolled sheets, galvanized sheets, aluminum sheets, etc., which are mainly used to manufacture various metal shells, cabinets, brackets and other structural parts. For example, products such as computer cases and distribution boxes are mostly completed through sheet metal processing.

There are obvious differences in processing principles and processes. CNC machining is based on computer digital control technology. Through pre-written programs, the tool's motion trajectory, cutting speed, feed rate and other parameters on multiple coordinate axes such as X, Y, and Z are precisely controlled to perform milling, drilling, boring, tapping and other machining operations on the material. It can realize complex three-dimensional machining, and the machining accuracy can reach the order of microns or even smaller. Sheet metal processing mainly involves process links such as cutting, bending, welding, and surface treatment. Cutting can be done by shearing machines, laser cutting, CNC punching machines, etc. to cut the sheet metal into the required shape; bending is to use a bending machine to bend the sheet metal into a specific angle; welding is used to connect multiple sheet metal parts; surface treatment such as painting and electroplating is used to improve the product's appearance and corrosion resistance.

The equipment composition is also completely different. CNC machining equipment is usually composed of a machine tool body, a CNC system, a drive device, a tool system, etc. The machine tool body provides a stable machining platform, the CNC system is its core, responsible for parsing and executing program instructions, the drive device controls the movement of the tool and the workbench, and the tool system is equipped with a variety of tools according to different machining needs. Sheet metal processing equipment includes shearing machines, bending machines, laser cutting machines, CNC punching machines, welding equipment, painting equipment, etc. Each equipment plays a role in a specific link of sheet metal processing.

Zhuhai Chuntian Machinery has in-depth involvement and excellent performance in both processing technologies. In the field of CNC processing, they rely on advanced CNC equipment and professional programming teams to accurately produce various types of high-precision parts for customers, meeting the strict requirements of high-end industries such as aerospace and automobile manufacturing for the accuracy and quality of parts. In terms of sheet metal processing, Zhuhai Chuntian Machinery has a complete range of sheet metal processing equipment and rich process experience. From the cutting of the sheet to the final surface treatment, it strictly follows the standard process to provide high-quality sheet metal structural parts for electronic equipment, electrical cabinet manufacturing and other industries. Whether it is the complexity and precision of CNC processing or the thin plate forming of sheet metal processing, Zhuhai Chuntian Machinery occupies an important position in the mechanical processing industry with its exquisite craftsmanship and reliable quality, and provides comprehensive and high-quality solutions for the diverse needs of different customers.

CNC machining and sheet metal machining have their own characteristics in terms of machining objects, principle processes, equipment, etc. They together build a rich system of modern mechanical machining, and Zhuhai Chuntian Machinery is a powerful promoter of this system.

Key Words