Zhuhai sheet metal processing: the firmness of solid rivets and blind rivets

Release time:

2025-01-16

Solid rivets have strong tensile strength, and blind rivets are easy to operate. Analyze their applications in scenarios such as automobile chassis processing, sheet metal riveting, and factors affecting firmness, to provide a basis for the reasonable selection of rivets.

Riveting is a common method for connecting sheet metal parts, and the choice of rivets is directly related to the firmness of the connection. Solid rivets and blind rivets are two common types, and they have different performances in terms of firmness. Understanding their characteristics is crucial to improving the quality of sheet metal processing, especially in areas such as automobile chassis processing where the connection strength is extremely high.

Solid rivets

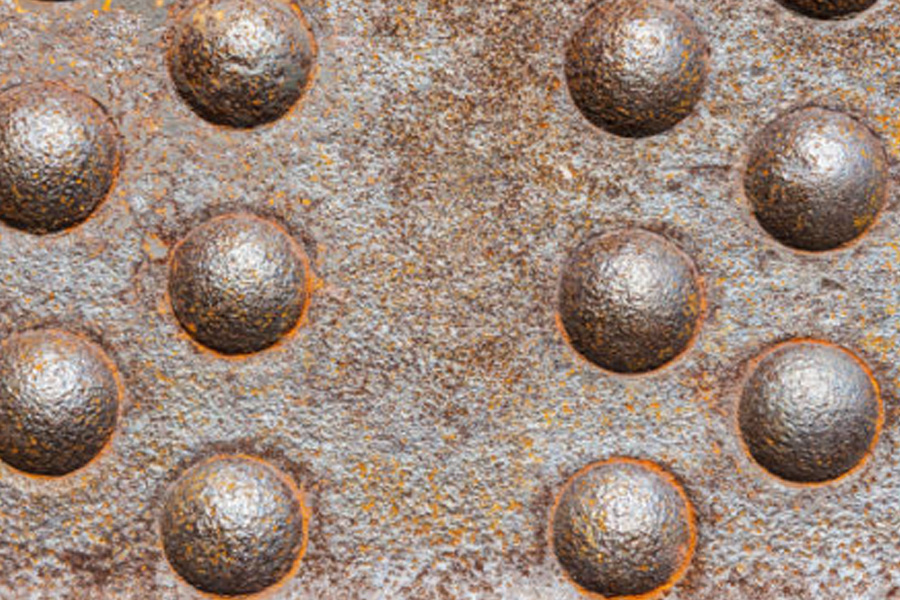

Solid rivets are named because of their solid structure inside. In operations such as Zhuhai sheet metal bending processing, they show strong tensile and shear resistance. When riveting, it is necessary to first drill a hole of appropriate size on the sheet metal to be connected, then insert the solid rivet into the hole, and use a special tool to rivet one end of the rivet to form a pier head to tightly lock the two sheets of metal.

This riveting method is widely used in automobile chassis processing. Because the chassis of the car is subjected to various complex stresses during driving, such as the impact force caused by road bumps and the inertia force caused by vehicle acceleration and deceleration. Solid rivets, with their solid structure, can effectively resist these external forces, ensure that the chassis components are firmly connected, and ensure driving safety. In the long-term use process, solid rivets are not easy to loosen, and can always maintain a high connection strength, providing reliable support for the car chassis.

Blind rivets

Blind rivets bring new convenience to sheet metal connections, and they also occupy an important position in Zhuhai sheet metal processing. Blind rivets consist of a rivet body, a rivet core, and a collar. When riveting, insert the blind rivet into the hole of the sheet metal, use a special rivet gun to clamp the rivet core and pull it hard, so that the rivet core drives the collar to deform, thereby tightly connecting the two sheets of metal together.

In some scenarios with high processing efficiency requirements, such as the assembly of small sheet metal parts in batch production, the advantages of blind rivets are highlighted. It is simple to operate and does not require complex riveting operations like solid rivets. It can quickly complete the connection and improve production efficiency. In the sheet metal riveting process, blind rivets can also adapt well, and achieve good connection effects through precise pressure control. Although there is a cavity inside the blind rivet from a structural point of view, through reasonable design and high-quality material selection, it can also provide sufficient firmness under normal use conditions. For example, in the processing of some automotive interior parts that require weight, the blind rivet can not only meet the connection strength requirements, but also conform to the design concept of lightweight automobiles due to its relatively light weight.

Factors affecting firmness

Whether it is a solid rivet or a blind rivet, its firmness is affected by many factors. The material of the rivet is one of the key factors. High-quality metal materials, such as high-strength aluminum alloy and stainless steel, can significantly improve the strength and durability of the rivet. The thickness and material of the sheet metal will also affect the riveting effect. Sheets of different thicknesses and materials need to choose rivets of appropriate specifications and materials to ensure the best connection firmness. In addition, whether the riveting operation process is standardized, such as the accuracy of drilling and the strength of riveting, is also directly related to the firmness of the rivet.

In Zhuhai sheet metal processing, solid rivets and blind rivets have their own advantages. Solid rivets, with their solid structure, play an irreplaceable role in areas such as automobile chassis processing with extremely high strength requirements; while blind rivets, with their convenient and efficient operation, have won a place in various sheet metal processing scenarios. Processing companies need to consider various factors according to specific application scenarios and product requirements, reasonably select rivet types, and strictly control the riveting process to ensure the firmness of sheet metal connections and produce high-quality sheet metal products.

This article compares the characteristics, application scenarios, and factors affecting firmness of solid rivets and blind rivets, and explains their importance in Zhuhai sheet metal processing. If you have other ideas about the content, such as adding or removing cases, adjusting the language style, etc., please feel free to propose them.

Key Words