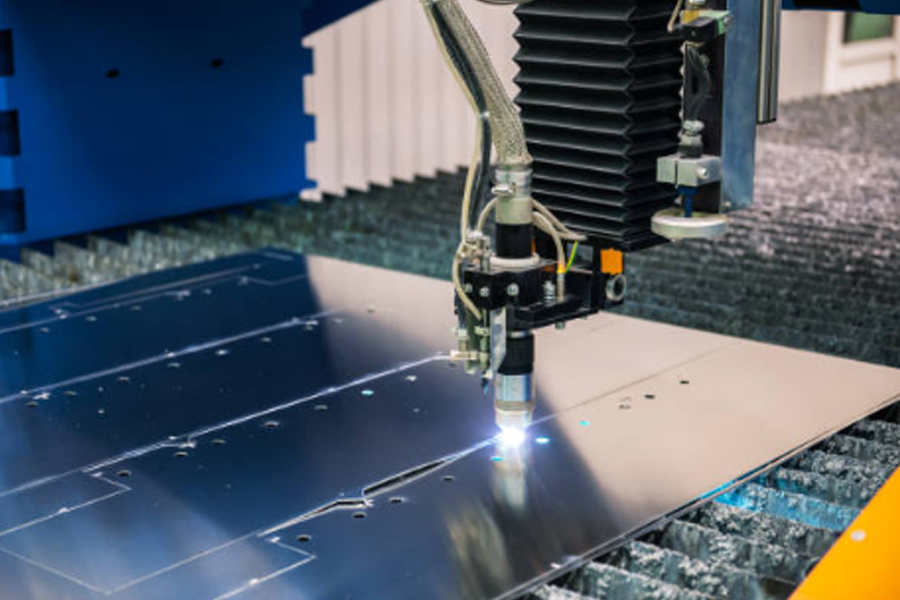

Sheet metal laser welding: A transformative force in the manufacturing industry

Release time:

2025-02-05

Sheet Metal Laser Welding Technology uses high-energy laser beams to achieve high-quality welds, improve production efficiency, reduce subsequent processes, meet appearance requirements, and is applicable to multiple fields. Faced with high investment and operational skills challenges, Chuntian Machinery Technology leads the development and promotes high-quality development of the manufacturing industry.

In today's era of rapid development of manufacturing, sheet metal laser welding technology is gradually becoming the focus of the industry.

Sheet metal laser welding uses lasers to generate high-energy laser beams. After optical fiber transmission, collimation and focusing, the materials at the joints are melted and cooled to form high-quality welds. Compared with traditional welding methods, such as manual argon arc welding and gas shielded welding, it has many advantages. Laser welding is fast, which can greatly improve production efficiency and weld a larger area per unit time; the heat input is extremely low, and the deformation after welding is very small, which reduces or eliminates the subsequent polishing and leveling processes and reduces labor costs; the weld appearance is beautiful and smooth, without defects such as pores and cracks, which can well meet the product appearance requirements; it can also achieve welding at any angle, and can weld inaccessible parts and various complex workpieces.

From the perspective of industry applications, sheet metal laser welding has shown unique advantages in home appliances, high-tech electronics, automobile manufacturing, high-speed rail manufacturing, precision machining and other fields. As the global manufacturing industry accelerates its transformation to intelligence and digitalization, the requirements for the accuracy, efficiency and quality of welding technology are constantly increasing, and sheet metal laser welding technology is undoubtedly in line with this development trend.

However, the technology also faces some challenges. On the one hand, the initial investment cost of laser welding equipment is high, which puts a lot of financial pressure on some small and medium-sized enterprises; on the other hand, operators need to have certain professional knowledge and skills to ensure the correct operation of the equipment and the reasonable setting of process parameters.

As a leader in the industry, Chuntian Machinery Technology has made unremitting efforts and innovations to deeply cultivate sheet metal laser welding technology. With the characteristics of sheet metal laser welding, such as high efficiency, high quality and flexibility, it leads the development trend in this field. It has been widely used in more fields and continuously promoted the high-quality development of the manufacturing industry.

Key Words