Sheet Metal for Inkjet Enclosures: Precision Fabrication

Release time:

2025-04-17

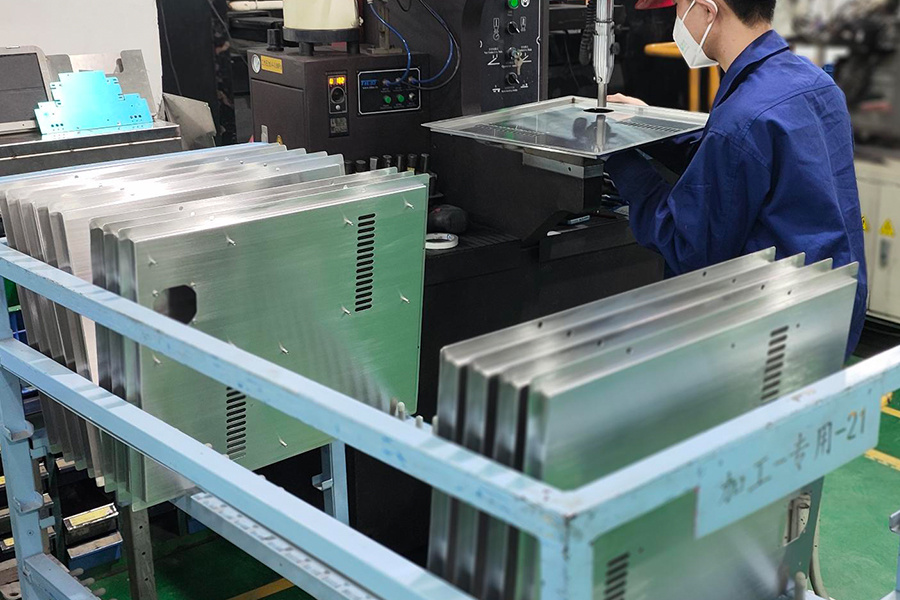

The inkjet printer chassis is a key barrier to the stable operation of the equipment. Our professional sheet metal processing services can ensure precise matching, long-term protection, and a balance between appearance and function. We focus on providing customized processing services for inkjet printer chassis, including demand analysis and design optimization, high-precision processing technology, surface treatment and quality inspection.

In industrial automation equipment, the chassis of the inkjet printer may seem simple, but it is the key barrier to the stable operation of the equipment. As a service provider focusing on sheet metal processing, we have been deeply involved in the manufacturing of inkjet printer chassis. We use our technical strength and industry experience to provide customers with high-precision and high-reliability sheet metal processing services, so that each device has a sturdy and durable "protective shell".

The importance of sheet metal processing of inkjet printer chassis

Inkjet printers are widely used in food, medicine, electronics and other industries. Their chassis not only need to accommodate precision components, but also need to withstand the challenges of complex working conditions-high temperature, humidity, vibration, dust and other environmental factors may affect the life of the equipment. And professional sheet metal processing services are the core guarantee to ensure the performance of the chassis:

● Precision matching: The internal components of the inkjet printer are complex, and the chassis needs to be accurately opened and bent to ensure that the circuit board, nozzle and other components are tightly fitted to avoid assembly problems due to size deviation.

● Long-term protection: High-quality sheet metal processing can improve the chassis's anti-rust, anti-vibration and heat dissipation capabilities, and extend the service life of the equipment.

● Consider both appearance and function: Smooth surface treatment and reasonable structural design can not only improve the appearance of the equipment, but also optimize the convenience of operation and maintenance.

Our sheet metal processing service: precise control of the whole process

From design to delivery, we focus on providing customized processing services for inkjet printer chassis to ensure that every link meets customer needs:

1. Demand analysis and design optimization

According to the drawings or samples provided by the customer, combined with the actual application scenarios of the inkjet printer (such as dustproof level, heat dissipation requirements), optimize the chassis structure design.

● Provide material suggestions: galvanized steel plate, stainless steel, aluminum alloy, etc., to balance cost and performance.

2. High-precision processing technology

● Laser cutting: ensure the precise opening position, smooth edges without burrs, and avoid damage to internal components.

● CNC bending: strictly control the bending angle and size to ensure the stability of the overall structure of the chassis.

● Welding and grinding: using argon arc welding and other processes, the welds are uniform and firm, the surface is finely polished, and there are no sharp corners.

3. Surface treatment and quality inspection

Provide treatment processes such as spraying, electroplating, and anodizing to enhance the corrosion resistance of the chassis.

● Full-process quality inspection: From the storage of raw materials to the shipment of finished products, carry out dimension verification, assembly testing, and protection performance verification to ensure 100% qualified delivery.

Why choose our processing services?

1. Focus on the industry and rich experience

Long-term service for inkjet printer manufacturers, well versed in the functional requirements and industry standards of the chassis, can quickly understand and implement customer needs.

2. Flexible response and efficient delivery

Support small batch customization and large-scale mass production, flexibly adjust production capacity, and shorten delivery cycle.

Emergency orders are prioritized to minimize customer waiting time.

3. Strict cost control and high cost performance

Through process optimization and material selection, help customers reduce processing costs while ensuring quality.

Service commitment: Make cooperation more worry-free

● Transparent communication: Provide progress feedback throughout the process and answer technical questions at any time.

● After-sales support: Provide technical consultation after delivery to assist in solving problems in assembly or use.

● Long-term cooperation: Establish customer files, continuously track product usage, and provide support for iterative needs.

Protect quality with craftsmanship

Sheet metal processing seems to be a "basic link" in the manufacturing industry, but it directly affects the reliability of equipment and brand reputation. We always believe that details make quality - whether it is millimeter-level precision control or the ultimate pursuit of protective performance, it is our solemn promise to customers.

Key Words