One-Stop Sheet Metal: Parts to Chassis, Full Precision

Release time:

2025-04-19

Our services focus on providing customized, high-precision, high-strength sheet metal processing for bus chassis to meet the corrosion resistance and load-bearing requirements of different scenarios. We provide a full range of sheet metal processing services, including design, processing, quality control, etc., to ensure that product quality meets industry safety standards.

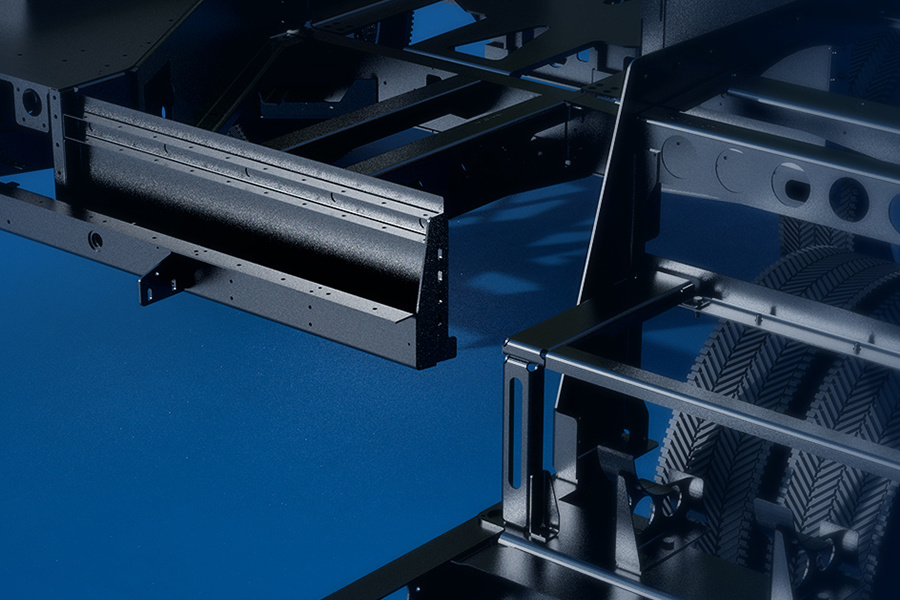

In the field of public transportation, the bus chassis is the core load-bearing structure of the vehicle, which is directly related to passenger safety and vehicle life. As a service provider focusing on sheet metal processing, we are deeply involved in the field of automobile manufacturing. With high-precision and high-strength processing technology, we provide reliable sheet metal solutions for bus chassis, helping customers build strong, durable and safe mobile carriers.

Core requirements for bus chassis sheet metal processing

The bus chassis has been subjected to the impact of complex road conditions, heavy load pressure and environmental erosion for a long time, which puts forward strict requirements for sheet metal processing:

● Structural strength: The chassis needs to bear the weight of the vehicle body and dynamic loads. The welding accuracy and material strength of the sheet metal parts directly affect the overall stability.

● Fatigue resistance: Frequent vibration and impact can easily lead to metal fatigue. The processing technology must ensure that the welds are uniform and stress-free.

● Rust and corrosion resistance: Environmental factors such as rainwater and snow melting agents require sheet metal parts to have long-term rust prevention capabilities to extend the service life of the chassis.

● Lightweight design: Under the premise of ensuring strength, reduce redundant weight through structural optimization to improve fuel efficiency and environmental performance.

Our sheet metal processing service: precise escort throughout the entire process

From design to delivery, we focus on providing customized sheet metal processing services for bus chassis, using technology and experience to ensure the quality and adaptability of each product.

1. Demand analysis and structural optimization

Combined with chassis functional requirements (such as load-bearing capacity, shock-absorbing design), optimize the sheet metal structure layout to balance strength and lightness.

● Provide material suggestions: high-strength steel, galvanized steel plate or aluminum alloy to match the corrosion resistance and load-bearing requirements of different scenarios.

2. High-precision processing technology

● Laser cutting: Ensure that the cutting edge of the plate is flat and the hole position is accurate to avoid assembly errors and stress concentration.

● CNC bending: Accurately control the bending angle and arc to ensure the geometric accuracy and overall rigidity of the chassis frame.

● Welding process: A combination of robot welding and manual repair welding is used to ensure that the welds are uniform and firm, and the hidden dangers of false welding are eliminated through flaw detection.

● Surface treatment: Sandblasting, rust removal, electrophoresis coating and other processes to enhance rust resistance and adapt to harsh environments.

3. Strict quality control

● Triple quality inspection system: raw material performance testing → semi-finished product size verification → finished product load simulation test to ensure compliance with industry safety standards.

● Full process traceability: Each batch of products can trace processing data and quality inspection records to ensure transparent and controllable quality.

Why choose our processing service?

1. Deep industry experience

Long-term service to automobile manufacturers, familiar with the design specifications and safety standards of bus chassis, and can quickly respond to customized needs.

2. Leading technology, efficiency guarantee

Advanced equipment (such as high-power laser cutting machine, CNC bending center) with mature technology, taking into account both precision and production capacity.

Support flexible delivery from prototype trial production to mass production, shortening customer R&D cycle.

3. Controllable cost, consistent quality

Through material utilization optimization and process standardization, help customers reduce comprehensive costs and eliminate "cutting corners".

Service commitment: make cooperation more worry-free

● Full transparent communication: from drawing confirmation to production progress, real-time synchronization of information to reduce communication costs.

● Quick response mechanism: Professional team provides 24-hour technical consultation, and urgent orders are prioritized.

● Worry-free after-sales guarantee: Provide technical support after delivery to help solve problems in assembly or use.

Protect every journey with professionalism

Sheet metal processing is the "invisible line of defense" for bus chassis manufacturing. We are well aware that the firmness of each weld and the accuracy of each sheet are related to the safety of the vehicle and the life protection of passengers. Use technology to consolidate quality and use responsibility to fulfill promises - this is our unchanging original intention.

Key Words