Stainless Steel Sheet Metal: Corrosion-Resistant Mixer Bases

Release time:

2025-04-20

As a key equipment in the production process, the stability, corrosion resistance and cleanliness of the liquid medicine agitator all place high demands on process technology. As a service provider focusing on sheet metal processing, we provide customers with reliable liquid medicine agitator sheet metal solutions with high-precision and high-cleanliness processing technology, helping customers achieve efficient and stable production goals.

In the fields of pharmaceuticals and chemicals, liquid medicine agitators are key equipment in the production process. Their core structure directly affects the uniformity of liquid medicine mixing, production safety and equipment life. As a service provider specializing in sheet metal processing, we provide reliable sheet metal solutions for liquid medicine agitators with high-precision and high-cleanliness processing technology, helping customers achieve efficient and stable production goals.

Core Challenges of Sheet Metal Processing of Liquid Medicine Agitators

Long-term contact with chemical solvents, high-temperature liquids or corrosive media by liquid medicine agitators poses unique requirements for sheet metal processing:

● Corrosion resistance: The material must resist the erosion of acids, alkalis and liquid medicines to avoid structural damage or pollution risks caused by rust.

● Sealing guarantee: The agitator shell and the joints must be tightly fitted to prevent liquid leakage or infiltration of external pollutants.

● Cleanliness requirements: The surface treatment must be smooth and without dead corners, easy to clean and disinfect, and meet the hygiene standards of the pharmaceutical industry.

● Structural stability: The frame rigidity must be maintained under high-speed operation to reduce the impact of vibration on mixing accuracy.

Our sheet metal processing service: Precise adaptation throughout the entire process

From design to delivery, we focus on providing customized sheet metal processing services for liquid medicine agitators, using technology and experience to ensure the high quality and functionality of each product.

1. Demand analysis and design optimization

● Scenario adaptation: According to the customer's application environment (such as pharmaceutical GMP standards, chemical explosion-proof requirements), stainless steel, titanium alloy or special coating materials are recommended to balance corrosion resistance and cost.

● Structural reinforcement: Optimize the shell thickness and rib layout to improve the pressure and impact resistance and ensure long-term stable operation.

2. High-precision processing technology

● Laser cutting: Ensure that the cutting edge of the sheet is smooth and burr-free to avoid residual impurities affecting the purity of the liquid medicine.

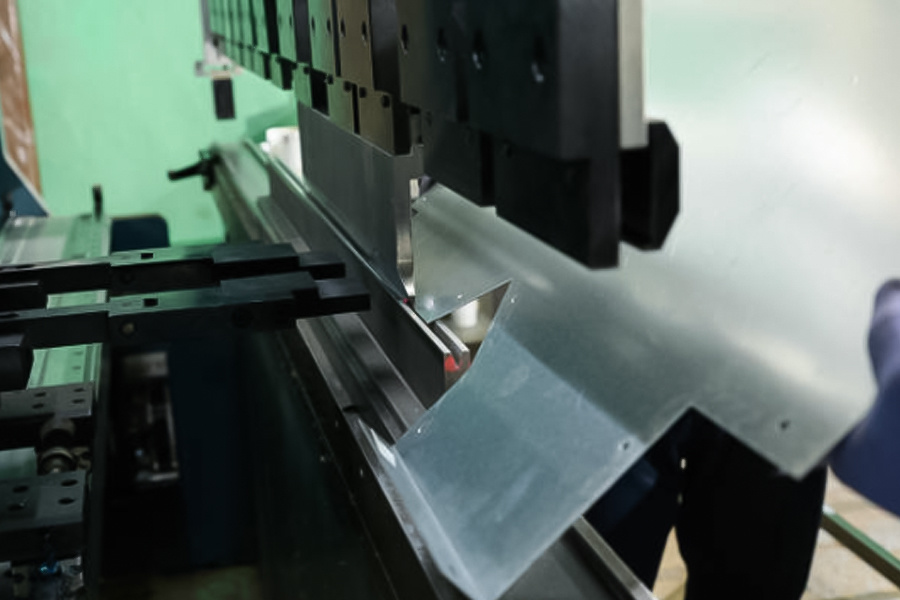

● CNC bending: Accurately control the bending angle and arc to ensure tight splicing of the shell and reduce welding gaps.

● Welding process: Use precision welding technologies such as argon arc welding to ensure uniform welds and no leakage risks, and the surface is polished to achieve food-grade finish.

● Surface treatment: Provide electrolytic polishing, passivation and other processes to enhance corrosion resistance and meet the requirements of sterile environment.

3. Strict quality control

● Triple quality inspection system: raw material composition detection → semi-finished product size verification → finished product sealing test to ensure compliance with industry safety regulations.

● Cleanliness guarantee: Avoid oil pollution during the entire processing process, and use dust-free packaging for key components to ensure delivery and ready for use.

Why choose our processing services?

1. Deeply cultivate the industry and understand the needs

Long-term service to pharmaceutical and chemical equipment manufacturers, familiar with the functional standards and regulatory requirements of liquid medicine mixers, and can quickly provide targeted solutions.

2. Technology and cleanliness are equally important

Advanced equipment (such as laser cutting machines, high-precision bending centers) are combined with clean production processes to take into account precision and hygiene standards.

Support flexible delivery from prototype development to mass production to meet the diverse needs of customers.

3. Balance between cost and quality

Through material selection optimization and process innovation, help customers reduce manufacturing costs, while eliminating the industry chaos of "sacrificing quality for low prices".

Service commitment: efficient response, worry-free throughout the process

● Transparent collaboration: from drawing confirmation to production progress, real-time communication throughout the process to ensure accurate implementation of needs.

● Fast delivery capability: regular orders are delivered in 10-15 days, and emergency needs are prioritized to minimize customer waiting time.

● After-sales technical support: provide welding process guidance, cleaning and maintenance suggestions after delivery, and help extend the service life of the equipment.

Professionally guard the purity of every drop of liquid medicine

Sheet metal processing is the "invisible guard" of liquid medicine agitator manufacturing. We are well aware that the sealing of each weld and the cleanliness of each sheet are related to the quality of medicines and production safety. Use technology to build a strong line of defense and use responsibility to fulfill commitments-this is our firm guarantee for customers.

Key Words