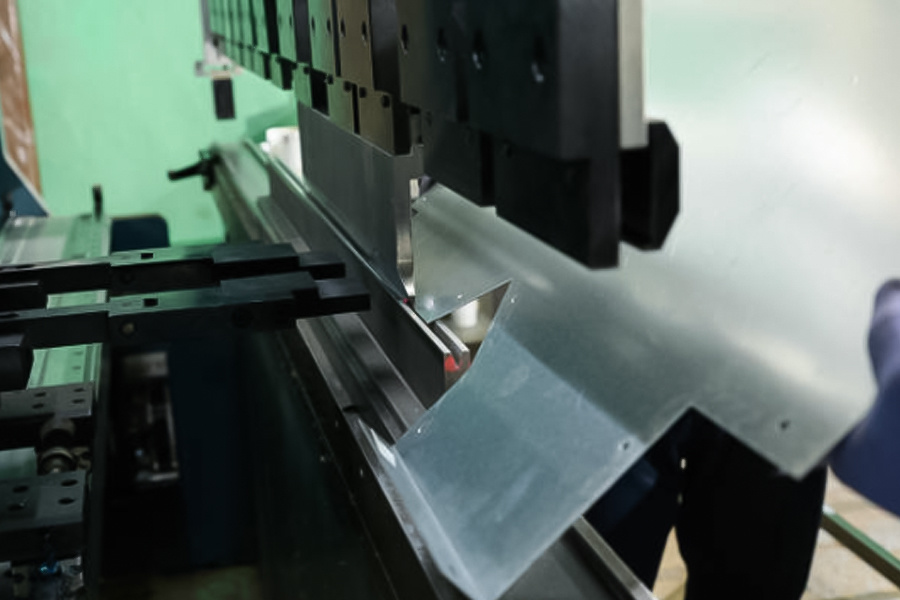

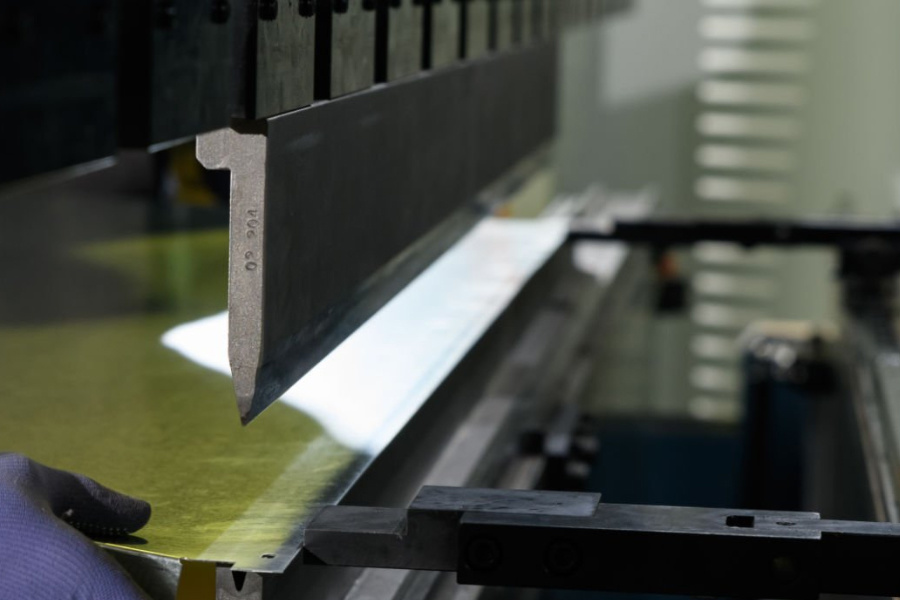

Small batch multi-variety sheet metal processing management solution

Release time:

2025-06-02

sheet metal processing

As the manufacturing industry transforms towards customization, sheet metal processing centers face the severe test of small batches and multiple orders. This not only tests the equipment capabilities, but also exposes the deep shortcomings of the traditional management system - how to solve the dilemma of efficiency and cost from the perspective of production management?

Four major management challenges of small batches and multiple varieties

1. Disordered production scheduling

● Order fragmentation leads to frequent equipment switching

● Emergency orders disrupt the original scheduling plan

2. Process inheritance gap

● Experience of old masters is difficult to standardize and reuse

● Repeated process verification of similar parts

3. Difficult quality traceability

● Mixed production of multiple batches is prone to mixed materials

● It is difficult to locate the responsible link for quality problems

4. Cost black holes breed

● Hidden model change losses devour profits

● Material stagnation rate increases with the variety

Three changes in intelligent management systems

1. Digital nerve center

● Intelligent dynamic scheduling optimizes equipment utilization

● Automatic order decomposition and priority determination

2. Process knowledge map

Structured storage of sheet metal processing parameters

Intelligent matching of historical optimal process solutions

3. Full process traceability system

Single-piece identity binding throughout the entire life cycle

Quality data drives process optimization in real time

Multiplier effect of management upgrade

● Efficiency leap: significant compression of model change preparation time

● Controllable costs: material turnover efficiency doubled

● Decision-making evolution: Real-time capacity visualization guide strategy

In the era of small batches and multiple varieties, the core competitiveness of sheet metal processing centers has shifted from single-machine performance to management systems. Only by building a new ecosystem of "intelligent scheduling + process inheritance + precise control" can the challenges of diversity be transformed into a sustainable source of profit.

Chuntian Machinery has been deeply involved in the sheet metal processing field for 22 years, and has transformed the core technology precipitation into:

● Intelligent management matrix covering 300+ process scenarios

● Dynamic scheduling engine to resolve mixed production of multiple varieties

● Full-link traceability system to eliminate quality fluctuations

Let every small batch order enjoy the benefits and quality of large-scale production

Key Words