Stainless steel equipment shell design specifications: IP protection level selection and anti-corrosion process illustration

Release time:

2025-06-27

The key links in the design of stainless steel equipment shells include IP protection level selection, anti-corrosion process and sealing surface technology. IP protection level is an international standard for dust and water resistance. Select the appropriate level according to the equipment use environment. Anti-corrosion process is the key to improving equipment durability, and passivation treatment is a key step in forming a protective layer.

Designing a durable stainless steel device housing is essential to ensure reliable operation of the precision components inside in a variety of environments. This article will focus on several key design aspects. First, it will explain in detail how to scientifically select the appropriate IP protection level based on the actual environmental conditions of the device to ensure that the housing can effectively block the intrusion of dust and water. Secondly, it will explore several core anti-corrosion processes, such as the critical passivation treatment and its key parameters, as well as the salt spray test specifications that verify the corrosion resistance of the housing. Finally, the article will analyze the core elements for achieving high sealing performance, including the design points of the sealing structure and the surface treatment technology that affects the protection effect. Together, this knowledge forms the basis for creating a highly protective, long-life stainless steel device housing.

IP protection level analysis

The IP protection level is an internationally accepted standard used to indicate the dust and water resistance of the device housing. It is graded by IP code, such as IP65, which means complete dust and low-pressure water jet protection. When choosing the right level, you need to consider the environment in which the device is used: IP54 can be selected in dry indoor places, while higher levels such as IP66 or IP67 are required outdoors or in wet areas such as industrial workshops to resist erosion by dust, rain or splashing water. These grades are often used for stainless steel equipment housings because their durability combined with IP protection can enhance overall reliability. The IEC 60529 standard defines these classifications and corresponds to the NEMA standard, helping users match them according to actual needs. In addition, environmental factors such as humidity or dust concentration directly affect the selection process to ensure that the housing can still protect internal components under harsh conditions.

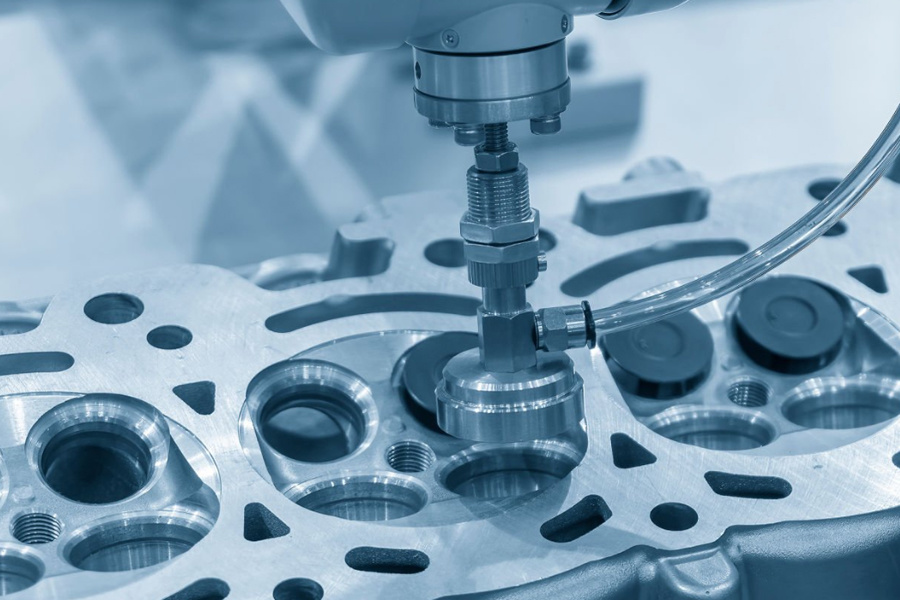

Anti-corrosion process diagram

The anti-corrosion process of stainless steel equipment housing is the core link to improve the durability of the equipment. It forms a protective layer through chemical treatment to prevent rust. For example, passivation treatment is a key step, using a specific solution to remove surface impurities; key parameters include treatment temperature and time. In addition, surface treatment technologies such as electroplating or spray coating can enhance corrosion resistance. Salt spray test specifications are used to verify the effect and simulate salt spray environment to test the corrosion resistance of the housing. These processes are combined to ensure that the housing can work reliably for a long time in a humid or corrosive environment.

Key points of sealing surface technology

The sealing performance of the equipment housing is directly related to whether the internal electronic components can effectively resist the intrusion of external water vapor, dust and even corrosive substances. The key to achieving reliable sealing lies in the surface treatment process and precise sealing structure design. For stainless steel housings, common sealing methods include laser welding to ensure the tightness of permanent joints, and the use of silicone or fluororubber sealing gaskets at the joints between the door panel and the box body. These gaskets need to be precisely designed with groove dimensions based on the amount of compression to ensure uniform pressure distribution on the contact surface. In addition, where there are moving parts (such as buttons and shafts) passing through the housing, special dynamic sealing structures must be used, such as rotating shaft seals or elastomer sealing sleeves, to prevent oil or rain from penetrating along the moving gaps. Precision surface flatness processing is also basic, and any tiny bumps may become leakage channels.

Based on the previous discussion, the design of stainless steel equipment housings needs to comprehensively consider the selection of IP protection levels, the application of anti-corrosion processes, and the design of sealing structures. Selecting the right IP level can ensure that the equipment is effectively protected in humid or dusty environments, while anti-corrosion treatments such as surface technology can extend the service life of the housing. At the same time, the design of the sealing structure prevents moisture and dust from intruding, improving overall reliability. These measures work together to create a corrosion-resistant, highly sealed, practical housing for industrial equipment that meets the needs of various working environments.

Key Words