What is precision in CNC machining?

Release time:

2024-09-05

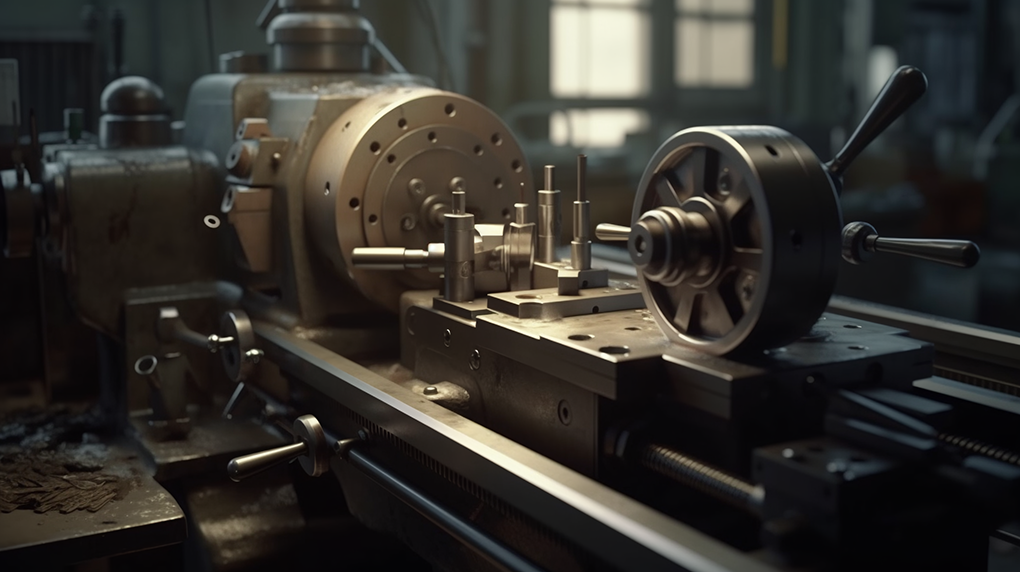

In modern industrial production, CNC machining technology plays a vital role. Whether it is the manufacture of industrial equipment or the production of packaging machinery, precision is a key consideration.

What is precision in CNC machining?

Precision refers to the degree of conformity between the actual geometric parameters (size, shape and position) of the parts after machining and the ideal geometric parameters. In CNC machining, precision is usually divided into dimensional accuracy, shape accuracy and position accuracy.

Dimensional accuracy refers to the degree of deviation between the actual size of the part and the designed size. For example, when manufacturing key parts of industrial equipment, dimensional accuracy requirements are extremely high, because even a small dimensional deviation may cause the equipment to fail to operate normally. For packaging machinery, dimensional accuracy is equally important. For example, the size of the packaging container must be accurate to ensure that the product is tightly packaged and beautiful.

Shape accuracy refers to the degree of deviation between the actual shape of the part and the ideal shape. For example, the cylindricality of shaft parts in industrial equipment is required to be high to ensure stability during high-speed operation. For parts such as cams in packaging machinery, the shape accuracy directly affects the accuracy and reliability of the packaging action.

Position accuracy refers to the degree of deviation between the actual position and the ideal position between the surfaces, between the axes, or between the surface and the axis on the part. In the assembly of industrial equipment, position accuracy determines the matching accuracy between various components, thus affecting the overall performance of the equipment. In packaging machinery, position accuracy is crucial for the coordinated action of the packaging mechanism.

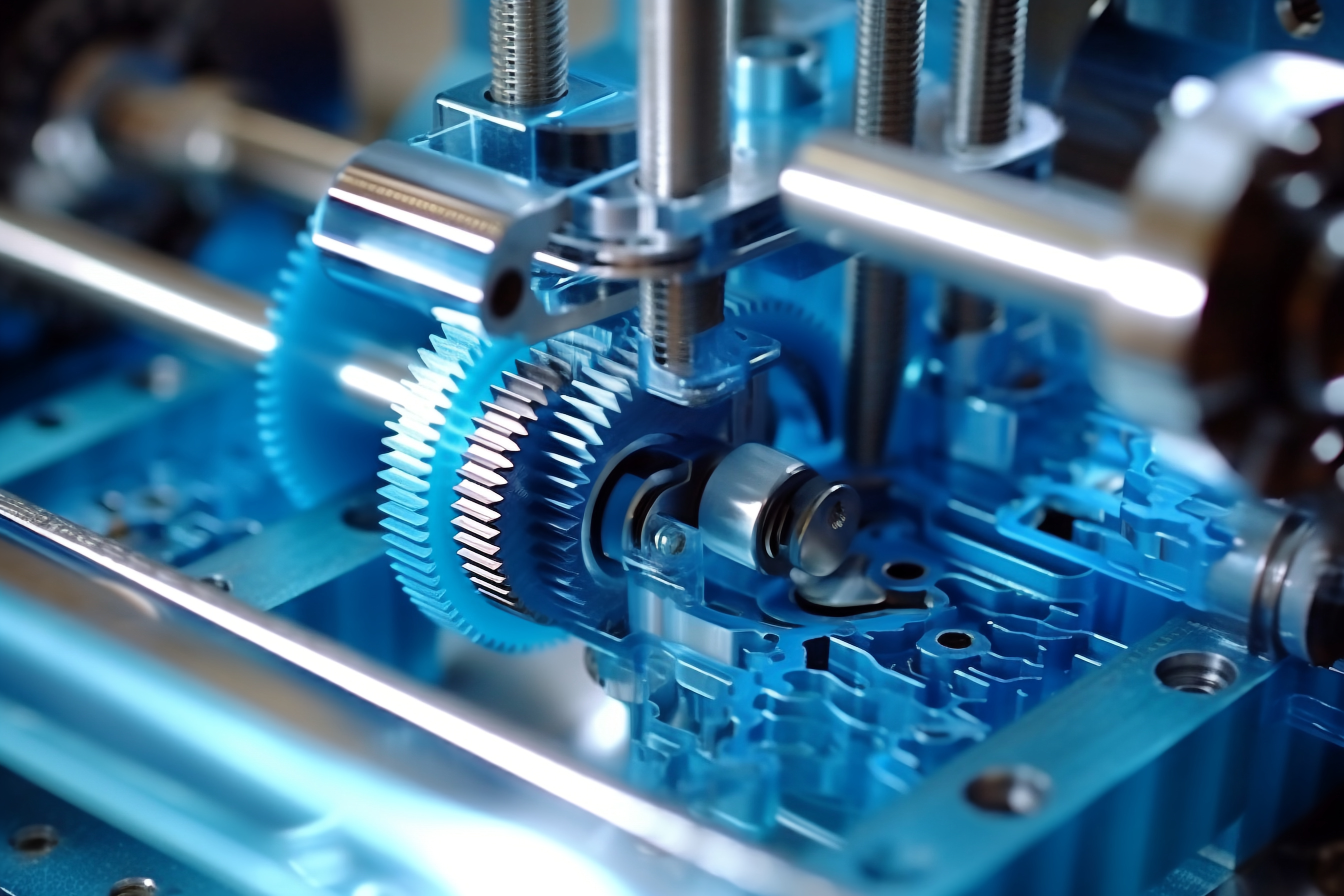

In industrial equipment manufacturing, high precision can ensure stable performance and reliable operation of the equipment. For example, a high-precision gear transmission system can reduce noise, improve transmission efficiency, and extend the service life of the equipment. High-precision machine tool parts can improve processing accuracy, thereby producing higher-quality industrial products.

In the field of packaging machinery, precision is also crucial. Packaging machinery usually works at a faster speed and has high precision requirements. For example, the feeding mechanism and sealing mechanism of the packaging machinery, the deviation of precision may lead to waste of packaging materials and unstable packaging quality. High-precision packaging machinery can improve packaging efficiency and meet the needs of modern industrial production.

Key Words