What is the tolerance of CNC machining?

Release time:

2024-09-07

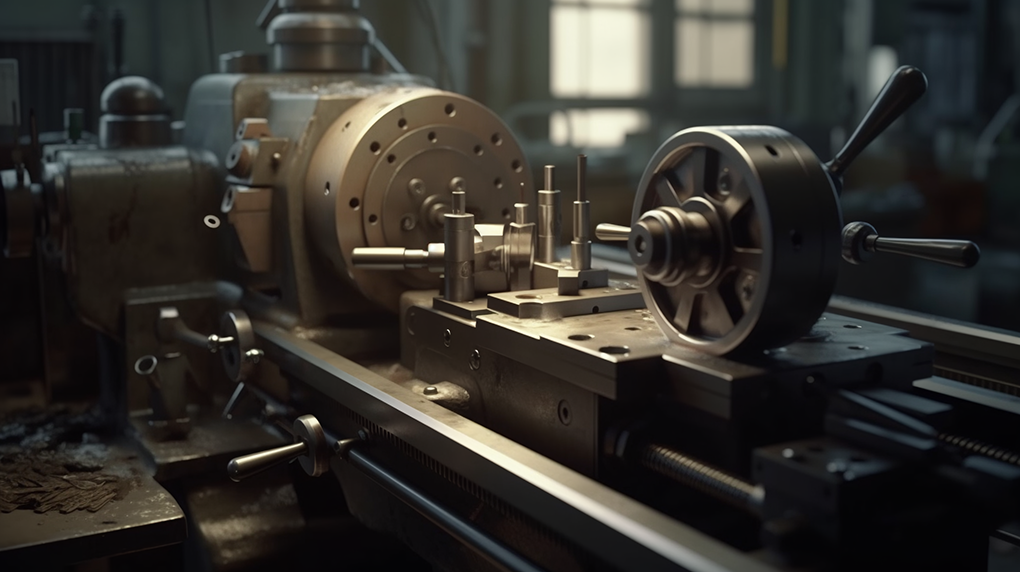

Tolerance is the amount of variation allowed in size. It is the allowable deviation range of size specified by the designer on the design drawing based on the product's use requirements and the feasibility of the manufacturing process. Tolerances are divided into dimensional tolerance, shape tolerance and position tolerance.

Dimensional tolerance refers to the amount of variation allowed in size. For example, if the diameter design size of a shaft is 50mm and the tolerance is ±0.05mm, then the actual diameter of the shaft is qualified between 49.95mm and 50.05mm. In the manufacture of industrial equipment and packaging machinery, reasonable determination of dimensional tolerance can improve production efficiency and reduce costs while ensuring product quality.

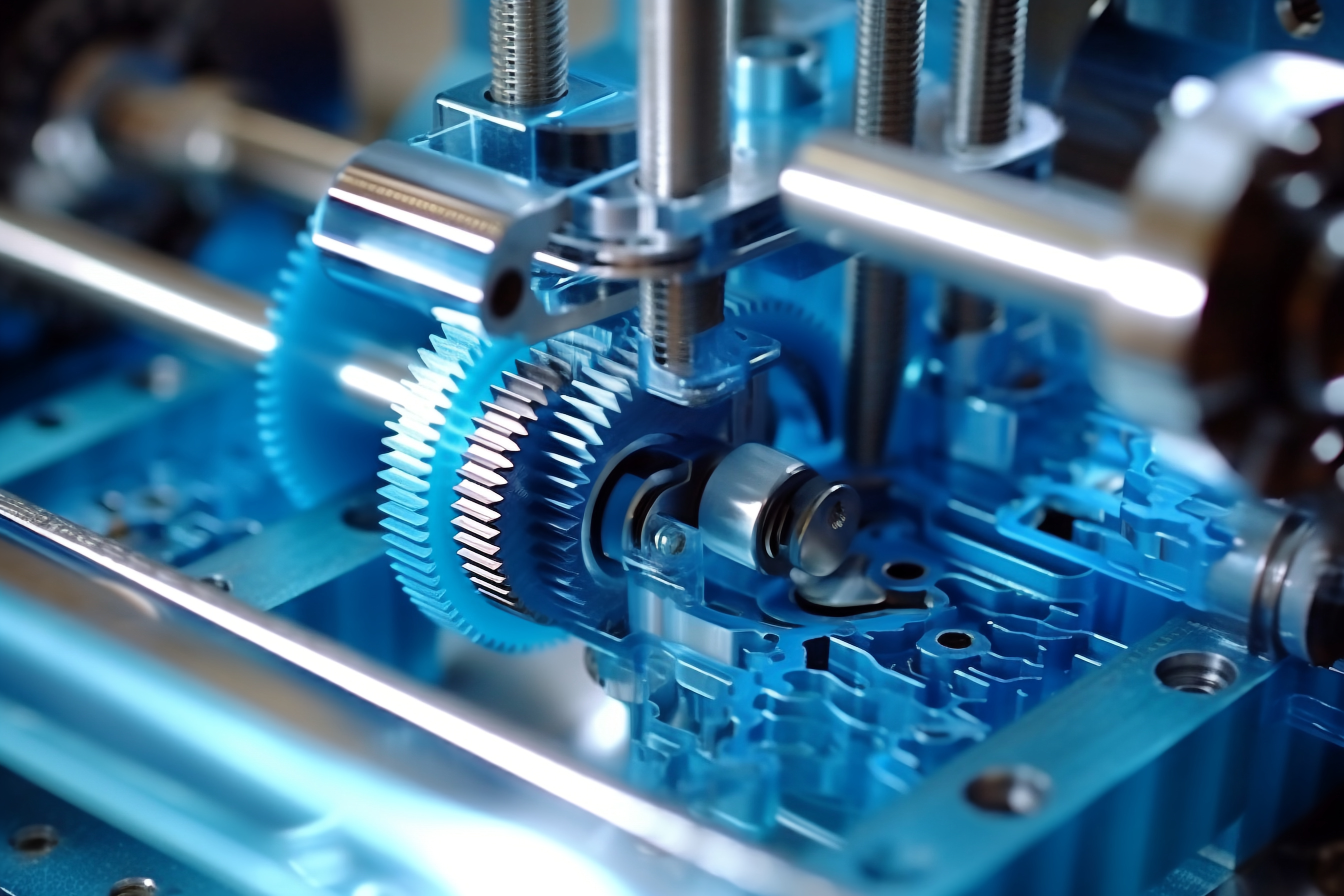

Shape tolerance refers to the total amount of variation allowed in the shape of a single actual element. Such as flatness, roundness, cylindricity, etc. In CNC machining, the control of shape tolerance is crucial to ensuring the function and assembly accuracy of parts.

Position tolerance refers to the total amount of variation allowed in the position of the associated actual element to the reference. Such as parallelism, verticality, coaxiality, etc. In the assembly of industrial equipment and packaging machinery, the control of position tolerance directly affects the performance and reliability of the equipment.

In the manufacturing of industrial equipment, reasonable tolerance design can reduce production costs and improve production efficiency. If the tolerance design is too strict, it will increase the difficulty of processing and increase the cost; if the tolerance design is too loose, it may affect the performance and quality of the equipment.

Key Words