Sheet Metal Rolling Technology

Release time:

2024-10-10

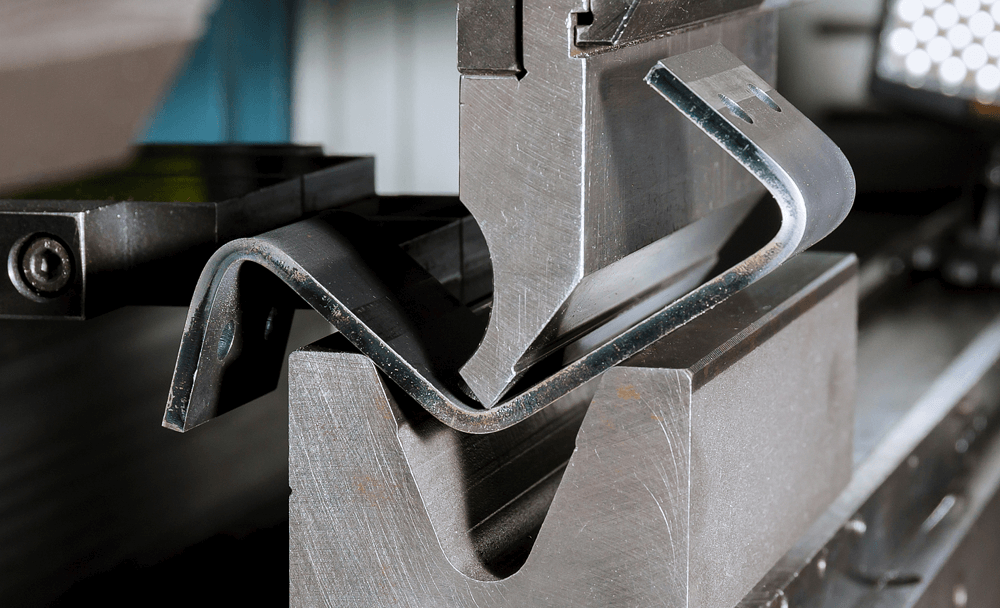

Sheet metal rolling is a processing method that continuously bends and forms metal sheets through a series of rotating rollers. In this process, the metal sheet is gradually rolled between the rollers, and as the rollers rotate, the sheet is subjected to uniform pressure and bending force to form the desired shape.

This technology is usually suitable for processing long strips of metal sheets, and can produce products with various cross-sectional shapes, such as channel steel, angle steel, I-beam, etc., as well as various arc-shaped, circular and special-shaped metal components.

Working principle of sheet metal rolling technology

The core of sheet metal rolling technology lies in the design and arrangement of rollers. Usually, a set of rollers consists of multiple rollers of different shapes and sizes, which are arranged on the rolling equipment in a specific order.

When the metal sheet enters the rolling equipment, it first passes through a set of pre-bending rollers, which gradually bend the edges of the sheet to prepare for subsequent forming. Then, the sheet enters the main forming roller area, where the sheet is subjected to greater pressure and bending force, gradually forming the desired cross-sectional shape.

During the rolling process, parameters such as the rotation speed, pressure and spacing of the rollers need to be precisely adjusted according to the material, thickness and desired shape of the sheet. Only in this way can the forming quality and precision of the sheet metal be ensured.

Characteristics of sheet metal roll forming technology

1. Efficient production

Sheet metal roll forming technology can achieve continuous production and greatly improve production efficiency. Compared with traditional processing methods such as stamping and bending, roll forming can process a large number of products in a short time, which is especially suitable for large-scale production.

2. High-precision forming

Since the shape and size of the roller can be precisely designed and manufactured, the roll forming technology can achieve high-precision forming. By adjusting the parameters of the roller, the bending angle, radius and thickness of the sheet metal can be controlled to ensure the accuracy and consistency of the product.

3. High material utilization rate

Roll forming technology can reasonably arrange the feed length and width of the sheet metal according to the shape and size of the product to minimize material waste. Compared with processing methods such as stamping, roll forming has a higher material utilization rate.

4. Good product quality

During the roll forming process, the sheet metal is subjected to uniform pressure and bending force, so the surface quality of the product is good and the internal stress distribution is uniform. This makes the roll-formed products have higher strength and rigidity, which can meet various complex use requirements.

Application fields of sheet metal roll forming technology

1. Construction field

In the construction industry, sheet metal roll forming technology is widely used to manufacture various metal structural parts, such as steel beams, steel columns, steel trusses, etc. These components not only need to have high strength and rigidity, but also need to have good appearance quality and corrosion resistance. Roll forming technology can meet these requirements and provide high-quality metal structural parts for the construction industry.

2. Automobile manufacturing

In the field of automobile manufacturing, roll forming technology can be used to manufacture the frame structure, doors, roof and other parts of the automobile body. These parts need to have high precision and strength, and also need to have good appearance quality. Roll forming technology can meet these requirements and provide an efficient and high-quality processing method for automobile manufacturing.

3. Machinery manufacturing

In the field of machinery manufacturing, roll forming technology can be used to manufacture various mechanical parts, such as shaft parts, gears, sprockets, etc. These parts need to have high precision and strength, and also need to have good wear resistance and corrosion resistance. Roll forming technology can meet these requirements and provide a high-quality processing method for machinery manufacturing.

4. Home appliance manufacturing

In the field of home appliance manufacturing, roll forming technology can be used to manufacture various home appliance shells and structural parts, such as the shells and frame structures of refrigerators, washing machines, air conditioners, etc. These parts need to have good appearance quality and strength, as well as high precision and dimensional stability. Roll forming technology can meet these requirements and provide an efficient and high-quality processing method for home appliance manufacturing.

Key Words