Zhuhai Chuntian Machinery Technology Co., Ltd.

Zhuhai Chuntian Machinery Technology Co., Ltd. was established in 2009. It is an international high-tech enterprise focusing on the research and development, production and sales of precision parts. The company's business involves auto parts, renewable energy products, medical equipment, power equipment, industrial parts, food equipment, photovoltaic energy storage products, compressor accessories.

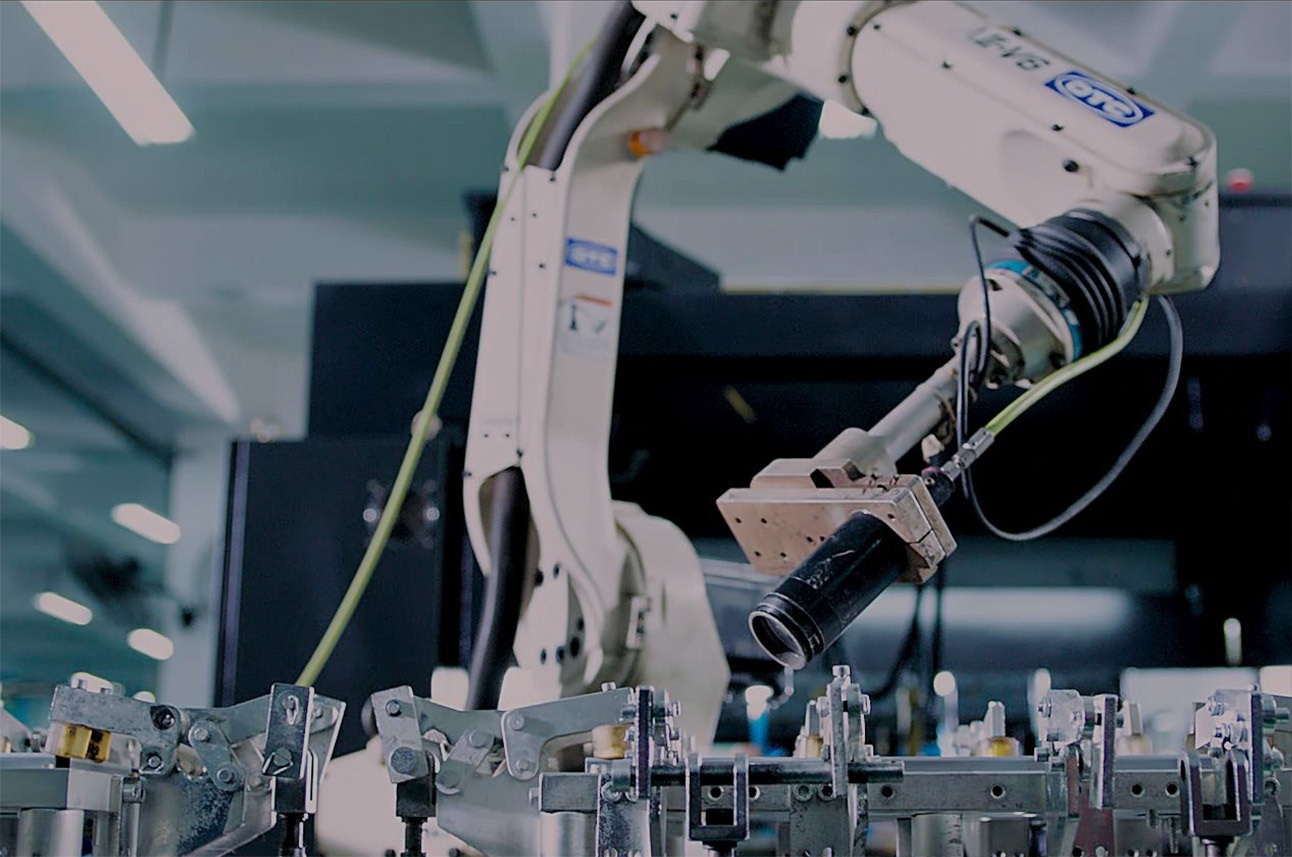

Through excellent lean management and information digitization system, the company builds CBS business system management platform, builds Chuntian intelligent manufacturing system, realizes the empowerment of manufacturing innovation and productivity innovation, and is committed to providing customers with advanced and reliable products and services.

We uphold the concept of winning long-term development advantages for customers and constantly achieve self-breakthrough, not only for their own requirements, but also to pursue the goal of mutual benefit and win-win cooperation with partners. We maintain a positive and open mind, operate in good faith, and move steadily.

In the future, the company will follow the corporate mission of "pursuing excellence, respecting nature and loving people", relying on innovative technology concepts, and outstanding talents as the forerunner, continue to play the manufacturing advantages of international high-tech industries, committed to exploration and innovation,and strive to become a pioneer of "Made in China 2025" strategy,showing the power of Chinese brands to the world.

The company was established in

Registered capital

Production workshop

Production Equipment

Number of employees

New Energy

Energy storage battery series, commercial energy storage, Pack battery pack series, communication energy storage, etc. Charging pile series

CTT aims to become a top new energy solution provider, promote technological innovation and industrial development, and provide customized new energy products to meet diverse needs.

Automotive

Bus chassis series, outer skin series, spare parts, etc.

CTT has the ability to collaborate and develop lightweight processing in the automotive industry, and provides comprehensive automotive application solutions.

Life Sciences

Pressure pumps, centrifuges, sensors, laboratory filter series, agitator series, biosafety cabinets, etc.

CTT has advanced equipment and a strict quality management system to provide high-quality products and services for global medical brands.

Medical Equipment

Dental torque wrench series, medical trolley series, shell series, ampoule crusher, etc.

CTT is committed to precision manufacturing in the medical industry, integrating innovative processes with strict quality control, providing high-precision processing and customized design, and promoting the development of medical technology.

Packaging Machinery

Laser marking machine, laser printer housing series, inkjet printer housing series, printer nozzle, etc.

CTT provides one-stop CNC processing solutions for the packaging industry, customizing efficient automation equipment, enhancing durability, and optimizing cost-effectiveness.

Smart Industry

Stamping die series, stage lighting series, metal detector series, etc.

CTT focuses on high-end CNC sheet metal products, using advanced processing technology, and serving multiple fields such as industrial automation.

Specialist industries

Energy Power

Automotive

Life Sciences

Medical Equipment

Packaging Machinery

Smart Industry

Global linkage, unbounded service

With its in-depth layout in the global supply chain, CTT has achieved a comprehensive upgrade of services. We have a number of front-end warehouses in Europe and production bases in the United Kingdom, Mexico, Thailand and other regions. No matter when and where, we always offer fast and flexible global delivery to ensure your business is responsive. Get in touch with CTT today to experience a professional service tailored to you.

View more

Customer Distribution

With DANAHER, CYTIVA, EXFO, KOHLER, MARTIN, VALEO, PALL, BECKMAN, VIDEOJET, CTC, PHENOMENEX(AGELA), SAMSUNG, ALEXANDER DENNIS, Ningde Times, Hesheng Co., Ltd., Panasonic Motor, Gree Lingda, Pioneer Intelligence, Deli, Sany Heavy Industry, etc. World-renowned enterprises to establish long-term friendly relations of cooperation.

Witness of honor

At present, the company's management system has passed the ISO9001/ISO14001/IATF16949/ISO13485/two integration management system assessment certificate/ASEM certificate/intellectual property management system certification.

The company has successively won the honorary titles of "National High-tech Enterprise", "Zhuhai key Enterprise Technology Center", "Guangdong Outstanding Entrepreneur", "Guangdong Stainless Steel Engineering Technology Center", "Guangdong contract-abiding and Credit-abiding Enterprise" and "caring Enterprise.

News Center

06

2025-06

The key links in the design of stainless steel equipment shells include IP protection level selection, anti-corrosion process and sealing surface technology. IP protection level is an international standard for dust and water resistance. Select the appropriate level according to the equipment use environment. Anti-corrosion process is the key to improving equipment durability, and passivation treatment is a key step in forming a protective layer.

06

2025-06

06

2025-06

06

2025-06