What are the types of sheet metal operations?

Release time:

2024-12-20

In-depth exploration of sheet metal operation types, cutting starts sheet metal shaping, bending gives shape, welding builds the whole, and surface treatment adds brilliance. Zhuhai Chuntian Machinery is unique in this field, with advanced equipment and professional teams, strictly controls each type of operation, creates exquisite sheet metal products in the aviation, automotive and other industries, and leads the new trend of industry technology.

In the field of sheet metal processing, there are many different types of operations, each of which plays a unique role in the process of transforming metal sheets into various practical products.

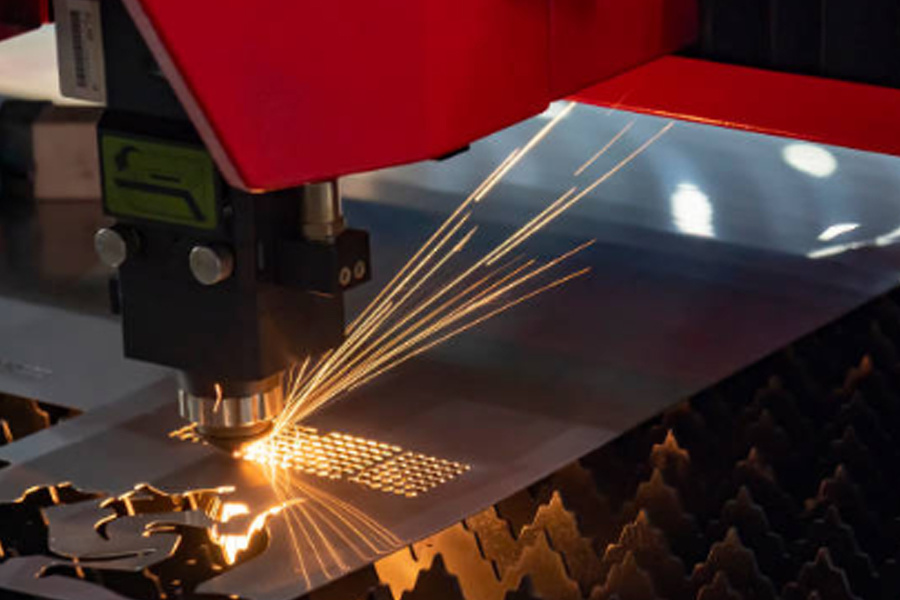

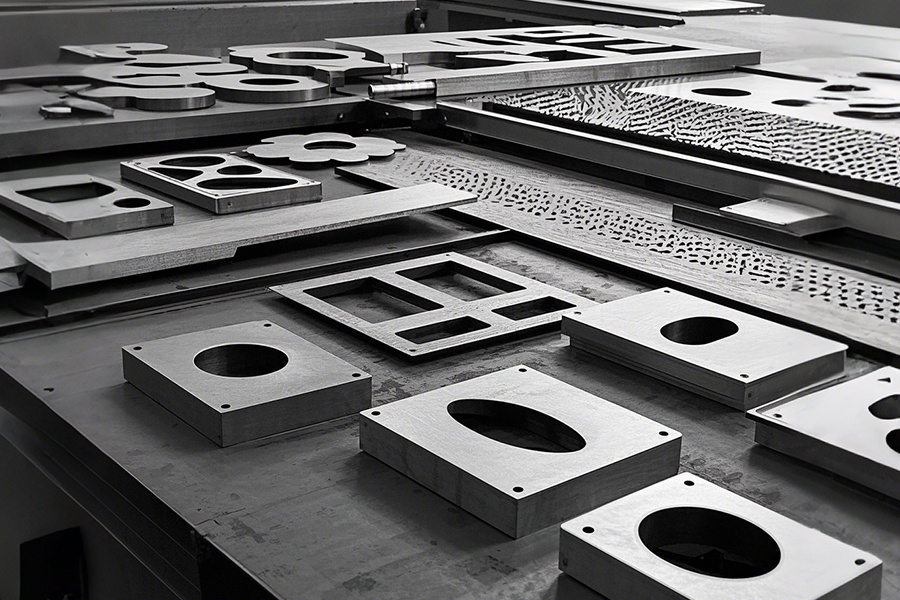

The first is the blanking operation. This is the initial step of sheet metal processing, and its purpose is to cut large pieces of metal sheets into suitable shapes and sizes according to design requirements. Common blanking methods include shearing machine blanking, laser cutting blanking and CNC punching machine blanking. Shearing machine blanking is suitable for straight-line cutting of sheets. It can quickly and efficiently cut large sheets into the required width and length. It is often used for large-scale blanking tasks that do not require particularly high precision. Laser cutting blanking can cut extremely complex shapes with a high-energy-density laser beam, and the cutting surface is smooth, the heat-affected zone is small, and the precision is very high. It has obvious advantages when processing precision sheet metal parts. CNC punching machine blanking can quickly punch out holes and contours of various shapes on the sheet through programming, and it is very efficient for sheet metal parts with many identical shape features. Zhuhai Chuntian Machinery has advanced blanking equipment, which can flexibly select appropriate blanking methods according to the design requirements of different sheet metal parts to ensure the accuracy and efficiency of blanking.

Bending operation is also a key link. It is the process of bending a flat metal sheet into a specific angle and shape. This requires a professional bending machine, and the operator accurately adjusts the mold and parameters of the bending machine according to the requirements of the drawing, such as the bending angle, bending radius, etc. In automobile manufacturing, some sheet metal parts of the car body need to be precisely bent many times before they can be formed. Bending operations require high skills and experience from operators, because even small errors may lead to assembly problems or appearance defects in the final product. Zhuhai Chuntian Machinery's bending technicians have undergone rigorous training and are proficient in bending techniques. They can accurately complete various complex bending tasks and ensure the dimensional accuracy and shape accuracy of sheet metal parts.

Welding operations are used to connect multiple sheet metal parts in sheet metal processing to build more complex structures. Common welding methods include argon arc welding and carbon dioxide shielded welding. Argon arc welding is suitable for welding thin plate materials and can produce high-quality welds with beautiful and high strength. Carbon dioxide shielded welding has the characteristics of fast welding speed and low cost, and is widely used in large-scale sheet metal structure welding. During the welding process, it is necessary not only to ensure the strength and sealing of the weld, but also to pay attention to controlling welding deformation. The welding team of Zhuhai Chuntian Machinery has superb technology, strictly follows the welding process standards, adopts appropriate welding methods and process parameters, and finely monitors the welding process to effectively ensure the welding quality and make the sheet metal structure firm and reliable.

In addition, there is a surface treatment operation. This operation is designed to improve the corrosion resistance and aesthetics of sheet metal parts. Common surface treatment methods include painting, electroplating, phosphating, etc. Painting can give sheet metal parts a rich variety of colors, and at the same time form a protective film on its surface to prevent the external environment from corroding the metal. Electroplating is to deposit a layer of metal plating on the surface of sheet metal parts, such as chrome plating, zinc plating, etc., which can not only enhance wear resistance, but also play a decorative role. Phosphating treatment is mainly to improve the coating adhesion on the surface of sheet metal parts and prepare for subsequent painting and other processes. Zhuhai Chuntian Machinery carefully selects the appropriate surface treatment process according to customer needs and the product's use environment, so that sheet metal parts can achieve the best results in performance and appearance.

Sheet metal operations include cutting, bending, welding, surface treatment and other types. Zhuhai Chuntian Machinery, with its advanced equipment, professional technical team and rigorous quality control system, has demonstrated excellence in every sheet metal operation, providing high-quality sheet metal products for many industries such as aerospace, automobile manufacturing, and electronic equipment. It occupies an important position in the sheet metal processing industry and continues to promote the development and progress of the industry.

Key Words