CNC grinding improves workpiece surface quality

Release time:

2024-11-02

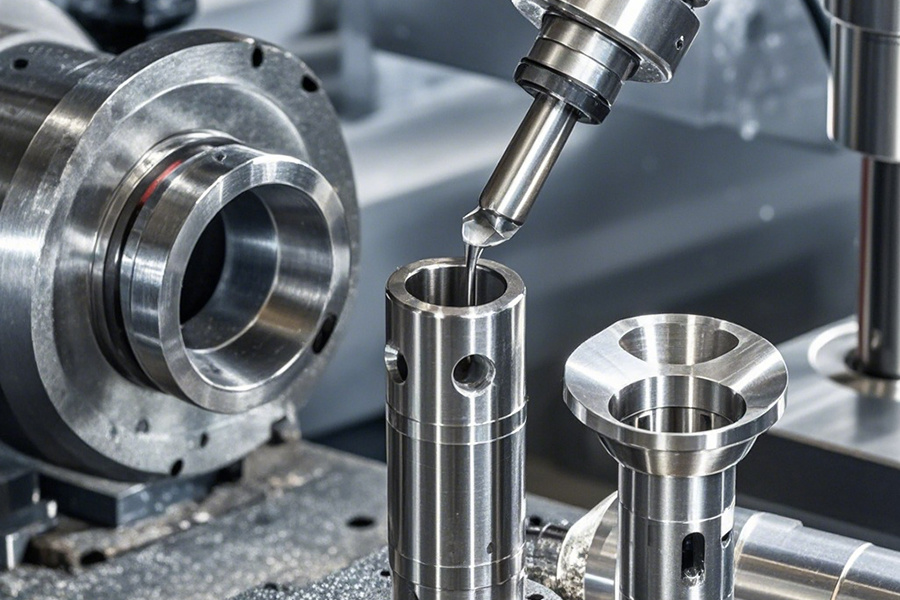

In the vast field of mechanical processing, honing has become a well-deserved tool in the field of precision machining of inner holes with its unique process and excellent performance. It has brought unprecedented precision improvement and quality assurance to many high-end manufacturing industries, and has left a strong mark in the process of modern industrial development.

In the vast field of mechanical processing, honing has become a well-deserved tool in the field of precision machining of inner holes with its unique process and excellent performance. It has brought unprecedented precision improvement and quality assurance to many high-end manufacturing industries, and has left a strong mark in the process of modern industrial development.

Honing is a method of finishing the surface of the inner hole of a workpiece using a honing tool. The principle is that the sand bar on the honing head contacts the surface of the inner hole of the workpiece with a certain pressure, and makes relative rotation and reciprocating motion. In this process, the abrasive grains on the sand bar continuously cut the workpiece material, thereby gradually removing the excess, so that the inner hole can reach high-precision size, shape and surface quality requirements.

Honing has several significant characteristics

1. It can obtain extremely high dimensional accuracy, and the inner hole dimensional accuracy can usually be controlled at the micron level. This is crucial for parts with strict precision requirements. For example, in the engine cylinder processing in the automotive field, accurate inner hole size is one of the key factors to ensure engine performance and fuel economy.

2. Honing can improve the roundness and cylindricity of the inner hole. Through the uniform cutting of the sand strip in the hole, the shape error of the hole generated in the previous processing can be effectively corrected, making the geometry of the inner hole more perfect.

3. The inner hole surface after honing has a cross-net pattern. This special surface texture is conducive to the storage and distribution of lubricating oil, which can reduce the friction coefficient during mechanical operation and increase the service life of parts.

Application field of honing processing

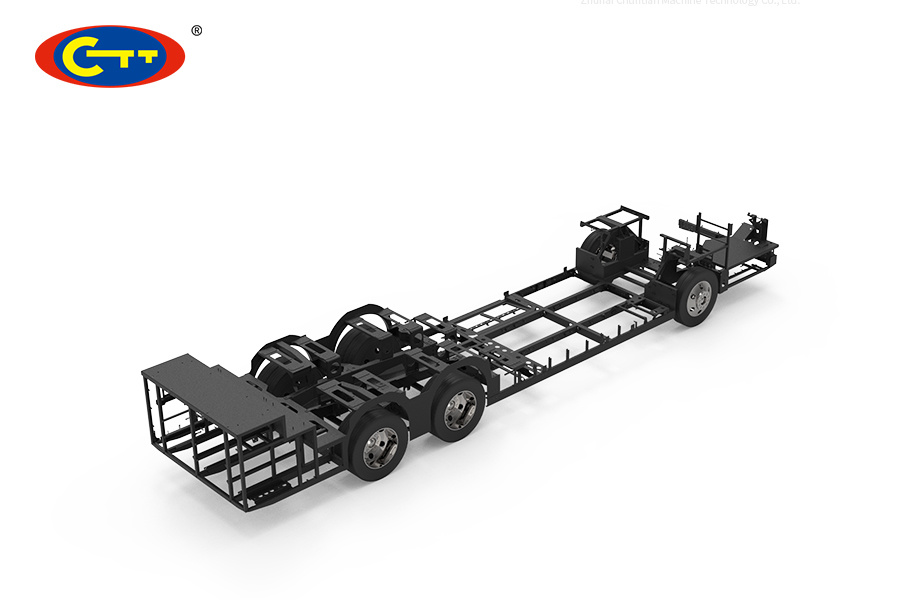

1. Honing processing has a wide range of applications in automobile chassis processing. There are many parts in the automobile chassis, such as steering knuckles, wheel hubs, etc., which contain inner hole structures. The quality of these inner holes directly affects the performance and safety of the chassis. Taking the steering knuckle as an example, the bearing mounting hole inside it requires extremely high precision and good surface quality. Through honing processing, it can ensure that the bearing and the hole are tightly and stably matched, reducing the vibration and wear caused by poor matching during the driving of the car. For the honing of the inner hole of the wheel hub, it can ensure the balance and stability of the wheel at high speed rotation, and improve the driving comfort and safety of the car. As an important part of the automobile, the application of honing processing technology ensures its reliability and durability, laying a solid foundation for the high-quality operation of the automobile.

2. In the food industry, there are also many equipment that require precision processing of inner holes, and honing processing also plays an important role. For example, some conveying pipelines and storage containers in food processing, their internal connection holes and valve holes, etc., need to meet the requirements of hygiene and precision. Honing processing can make the surface of these inner holes smooth, without burrs and rough textures, so as to prevent food residues from remaining in the holes, avoid bacterial growth, and meet food hygiene standards. Moreover, the precise inner hole size can ensure the sealing of pipeline connections, prevent food leakage, and ensure the safety and stability of the food processing process.

3. Some parts in stage lighting equipment are also inseparable from honing processing. For example, the inner hole of the rotating shaft in the lighting equipment and the inner hole of the lens adjustment device all require high-precision processing. In stage performances, the lighting equipment needs to adjust the angle and focal length frequently, which requires the relevant mechanical structure to move flexibly and accurately. The inner hole processed by honing can make the movement of the rotating shaft and the adjustment device smoother and reduce the jamming phenomenon, so as to ensure that the lighting engineer can accurately control the lighting effect and present a wonderful stage visual feast for the audience.

With the continuous advancement of science and technology, honing processing technology is also developing continuously, which is mainly reflected in the following three aspects:

1. The degree of automation is getting higher and higher. From the automatic setting of honing parameters to the automatic monitoring of the processing process, manual intervention is reduced, and the processing efficiency and quality stability are improved.

2. New honing tools and abrasives are constantly emerging. For example, the application of superhard abrasives further improves the processing efficiency and accuracy of honing, which can remove the excess faster and obtain better surface quality.

3. The integration with digital manufacturing technology is also an important trend. Through technologies such as CAD/CAM, the honing processing path and parameters can be planned more accurately, and more complex inner hole shapes can be precisely processed.

As an advanced inner hole precision processing method, honing processing has an indispensable position in many fields such as automobile chassis processing, food industry, stage lighting, etc. With its unique processing advantages, it meets the strict requirements of different industries for inner hole accuracy, shape and surface quality. With the further development of technology, honing will surely play a greater role in more fields and provide strong support for the high-quality development of modern manufacturing industry.

Key Words