Carving and processing: giving materials an artistic soul

Release time:

2024-11-05

Among them, engraving processing is like a magical artist, giving various materials a unique artistic soul.

In today's era of rapid technological development, mechanical digital control processing technology is constantly innovating. Among them, engraving processing is like a magical artist, giving various materials a unique artistic soul.

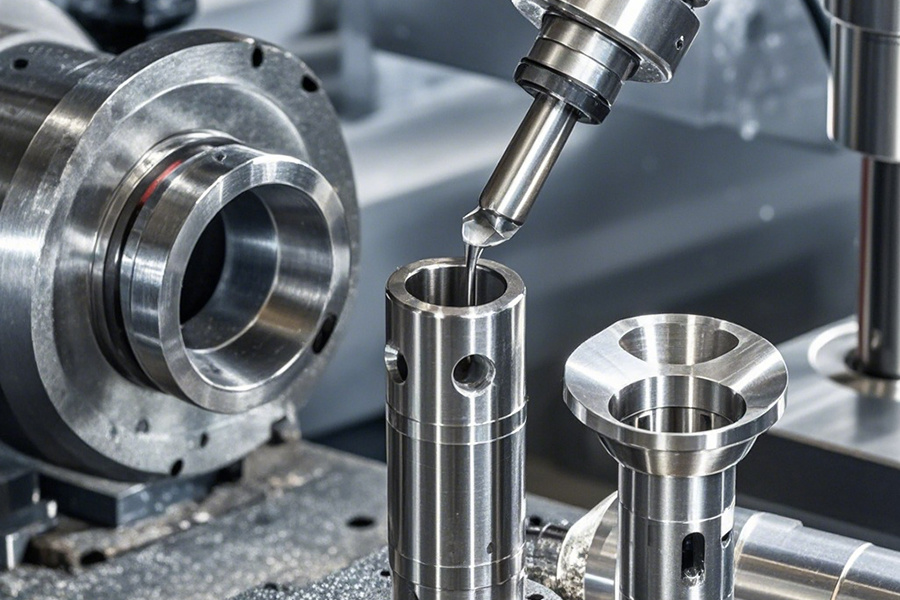

Engraving processing uses advanced CNC technology to accurately control the tool to cut and carve on the surface of the material, thereby creating exquisite patterns and shapes. This processing method has a high degree of accuracy and repeatability, and can achieve the perfect presentation of complex designs.

In the field of intelligent industry, engraving processing plays an important role. With the continuous advancement of intelligent manufacturing, the appearance and functional components of many industrial products require fine engraving processing. For example, the shells of some electronic products can be engraved with unique textures and logos, which not only increases the beauty of the product, but also enhances the brand recognition. At the same time, in the manufacture of some precision instruments, engraving processing can achieve high-precision patterns and marks on tiny parts, providing important support for the realization of instrument functions.

The automotive field is also one of the important application scenarios of engraving processing. In the processing of automobile chassis, some key components may be engraved to enhance their structural strength and beauty. In addition, engraving processing technology is often used in the design of automobile interiors. For example, the leather of car seats can be engraved with exquisite patterns, and the panels of the center console can be inlaid with engraved decorative parts, which add a sense of luxury and artistic atmosphere to the car. In terms of car appearance, some high-end car brands will perform engraving decorations on specific parts of the car body, making the car a flowing work of art.

The field of stage lighting is also inseparable from the contribution of engraving. The shell and lampshade of stage lighting equipment often need to be uniquely designed to create a variety of fantastic light and shadow effects. Engraving can create complex patterns and textures on these parts. When the light passes through these engraved parts, it will produce colorful light and shadow changes, adding infinite charm to the stage performance. For example, in a musical performance, the engraved patterns on the stage lighting equipment can change color and brightness as the plot develops, bringing a more immersive viewing experience to the audience.

So, how does engraving give the material the soul of art?

First of all, creative design is the key. Designers of engraving need to have rich imagination and artistic literacy. They conceive unique patterns and shapes according to different material properties and application requirements. These designs should not only be beautiful, but also take into account the processability of the material and the final artistic effect. For example, when designing a wooden craft, the designer may combine the texture and color of the wood to design a pattern that blends with natural elements to make the work more vital.

Secondly, proper material selection is crucial. Different materials have different textures, hardness and colors. Choosing the right material is an important step in giving the material an artistic soul. For example, metal materials can present a tough texture and luster, which is suitable for making modern style carvings; while wood has a warm texture and natural texture, which is more suitable for making traditional style crafts. At the same time, the quality of the material also directly affects the quality of the carving work, so strict control is required when selecting materials.

Furthermore, exquisite craftsmanship is a guarantee. Carving processing requires high-precision CNC equipment and skilled operators. During the processing process, the selection of tools, the setting of cutting parameters, and the planning of processing paths all need to be carefully designed and adjusted. Only through exquisite craftsmanship can the pattern on the design drawing be perfectly presented on the material, giving the material a true artistic soul. For example, when carving a jade craft, very fine knives and slow cutting speeds are required to ensure that the texture and color of the jade are not damaged.

Engraving processing, a type of mechanical digital control processing, has given various materials an artistic soul with its unique charm. Its wide application in the fields of intelligent industry, automobiles, and stage lighting has demonstrated the great potential and value of engraving processing. With the continuous advancement of technology, it is believed that engraving processing will play a more important role in future artistic creation and industrial manufacturing.

Key Words