Spinning: a unique process for metal forming

Release time:

2024-11-06

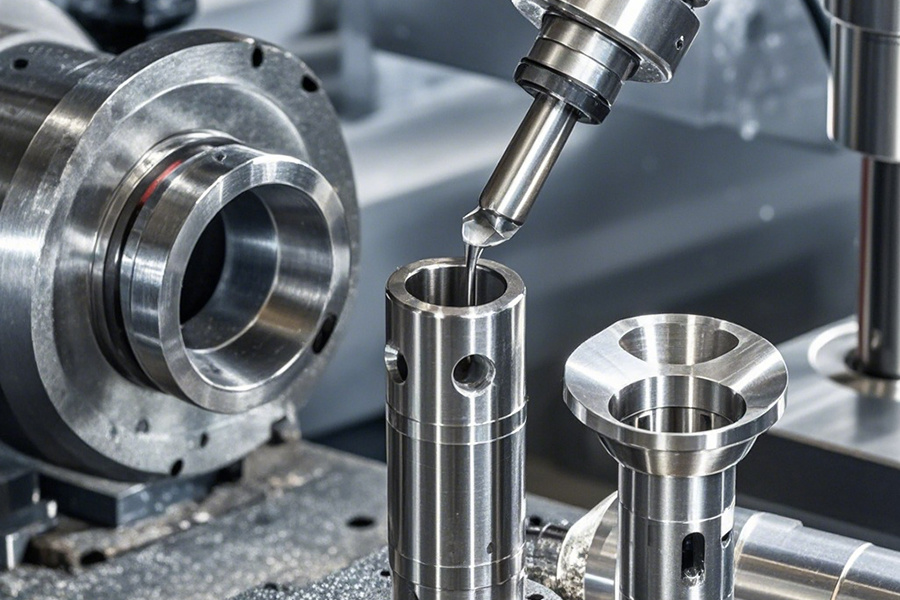

Spinning is a process that uses a rotating mold and pressure to gradually deform metal sheets or tubes.

Spinning is a process that uses a rotating mold and pressure to gradually deform metal sheets or tubes. During the process, the metal material is fixed on the rotating core mold, and the spinning wheel applies pressure to the material along a specific trajectory, so that the material fits the shape of the core mold under the combined action of centrifugal force and pressure, thereby realizing metal forming.

This process can be divided into ordinary spinning and strong spinning. Ordinary spinning mainly changes the shape of the metal material, and the thickness change is relatively small; while strong spinning will cause the metal material to have a larger change in the thickness direction, and can produce more complex shapes and higher strength parts.

Advantages of Spinning

High Precision

Spinning can achieve high forming accuracy through precise automated control. The motion trajectory of the mold and the spinning wheel can be accurately controlled, so that the dimensional error of the processed parts is extremely small. Whether it is a complex curved surface or a fine contour, it can meet the design requirements.

High Material Utilization

Compared with some traditional metal processing processes, spinning does not produce a large amount of waste. Metal materials are gradually deformed during the spinning process, and almost no excess material is removed, which is of great significance for saving costs and resources.

Good mechanical properties

The metal fiber structure inside the metal parts after spinning is optimized. This fiber structure is distributed along the shape of the parts, which improves the strength and toughness of the parts.

Application of spinning in different fields

Automobile field

In the processing of automobile chassis, spinning technology has an important application. Some key components of automobile chassis, such as wheels, brake drums, etc., need to have high strength and high precision. Spinning can produce parts that meet these requirements and improve the overall performance and safety of the automobile chassis. At the same time, in other parts of the car, such as exhaust pipes and other metal parts with special shapes, they can also be manufactured by spinning to improve the quality and performance of the car.

Food industry

In the food industry, spinning is also used in the manufacture of some metal containers. For example, some cans with special shapes, metal liners in food processing equipment, etc. Spinning can ensure the sealing and smoothness of these containers, while meeting food hygiene standards and ensuring the safety of food during processing and storage.

Stage lighting

The design of stage lighting equipment often pursues unique shapes and high-quality lighting effects. Spinning can create a variety of creative shapes for stage lighting shells, lampshades and other parts. The lampshades made by spinning can better control the scattering and reflection of light, creating colorful stage lighting effects and bringing a visual feast to the audience.

Key Words