Characteristics and advantages of boring processing

Release time:

2024-11-14

The characteristics and advantages of popular boring processing, covering automotive, food, stage lighting and other fields, to show its importance in modern machining.

In the field of modern mechanical processing, boring processing, as an important processing method, has unique characteristics and significant advantages. It plays an important role in many industries such as the automotive field, food industry, stage lighting, etc.

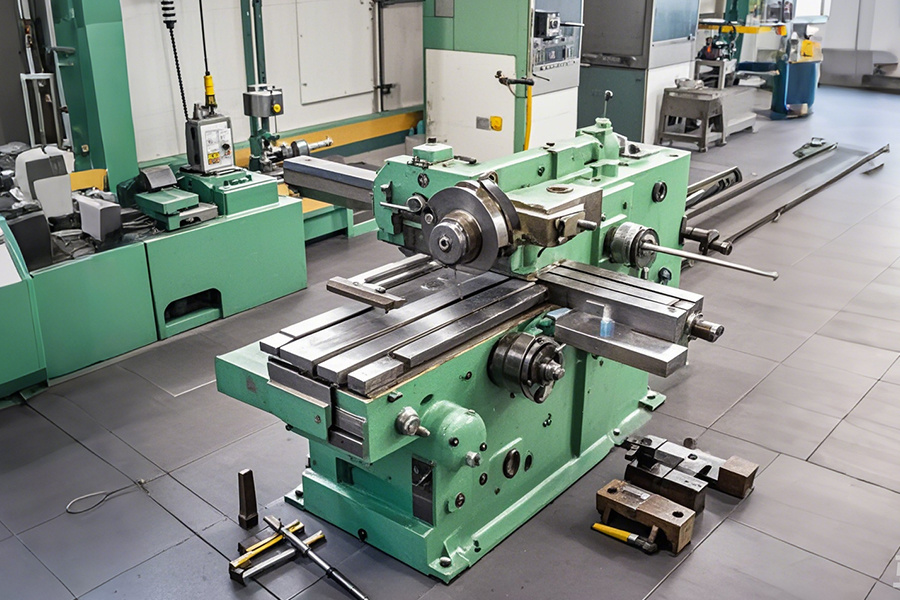

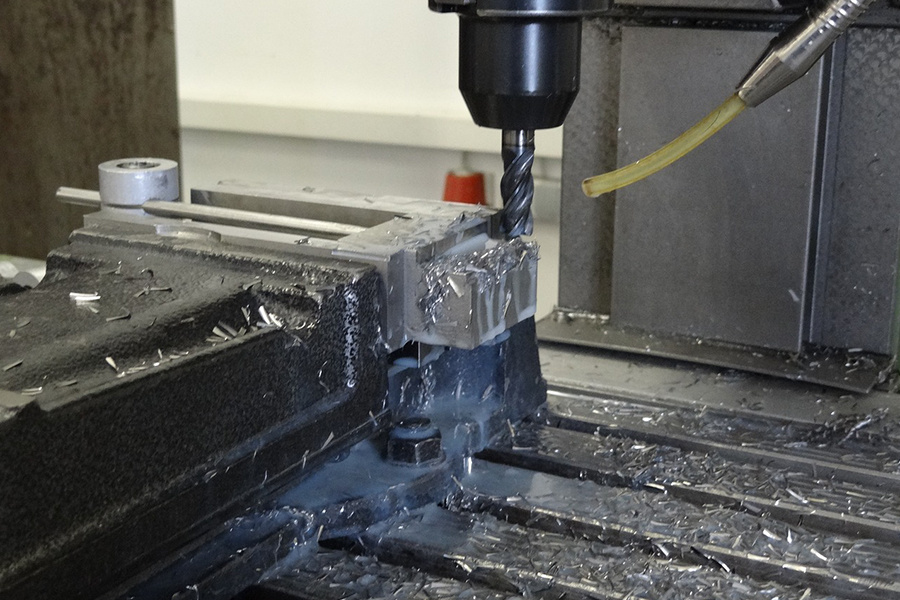

Boring processing is a processing method that uses a boring tool to enlarge an existing hole or process a high-precision hole. Boring tools are usually mounted on boring machines and use rotation and feed motion to cut the workpiece.

Boring processing can produce holes of various shapes and sizes, including circles, squares, ovals, etc. At the same time, boring processing can also finish the inner wall of the hole to improve the surface quality and dimensional accuracy of the hole.

Characteristics of boring processing

1. High processing precision

Boring processing can achieve high-precision hole processing, and its dimensional accuracy can reach the micron level.

In automobile manufacturing, the hole machining accuracy of key components such as engine blocks and transmission cases requires very high accuracy. Boring operations meet these stringent accuracy requirements, ensuring automotive performance and reliability. For example, the piston hole on the engine block requires extremely high dimensional accuracy and cylindricity, and its quality can only be guaranteed through boring processing.

2. Wide adaptability

Boring processing can process workpieces of various materials, including metals, non-metals, etc.

In the food industry, some parts of food processing equipment require high-precision hole processing. Boring processing can process stainless steel, plastic and other materials to meet the hygiene and corrosion resistance requirements of the food industry. For example, the valve holes on food filling equipment need to be processed with corrosion-resistant materials, and boring processing can well adapt to this demand.

3. High processing efficiency

With the continuous development of modern boring machine technology, the efficiency of boring processing is also constantly improving.

In the manufacturing of stage lighting equipment, a large number of high-precision holes are required to install various optical and electronic components. Boring processing can quickly process these holes and improve production efficiency. For example, the mounting holes on the reflector base of stage lights need to be processed in a short time to meet the needs of stage performances.

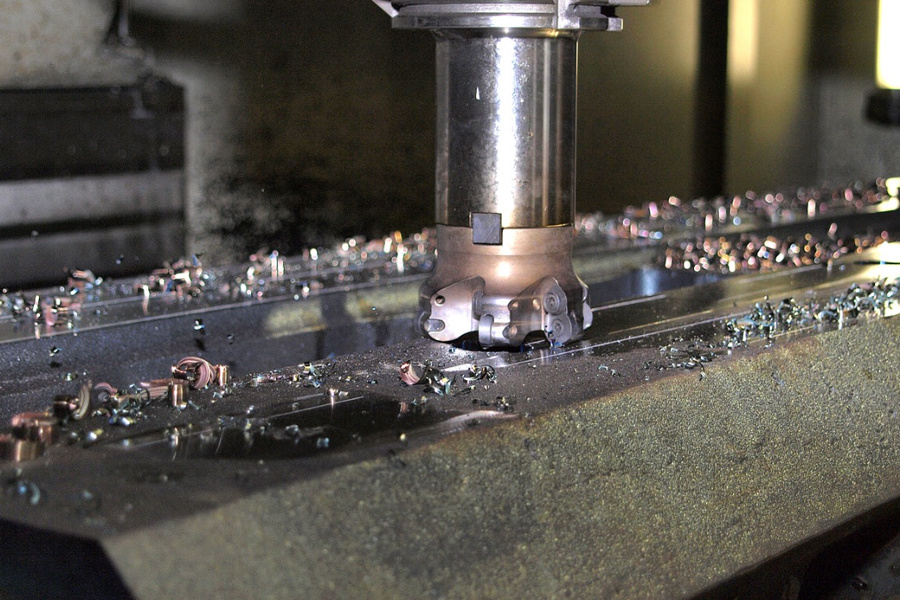

4. Can process complex holes

Boring processing can process holes of various complex shapes, such as step holes, blind holes, eccentric holes, etc.

In the design of automobile engines, some complex hole structures often appear. Boring processing can process these complex holes by adjusting the shape and feed method of the boring tool. For example, the oil hole on the engine crankshaft has a complex shape and requires a special boring tool for processing.

Advantages of boring processing

1. Improve product quality

Due to the high precision of boring processing, the quality of the product can be greatly improved.

In automobile manufacturing, high-precision hole processing can reduce engine friction and wear and improve engine efficiency and life. At the same time, it can also improve the overall performance and safety of the car. For example, the accuracy of the brake disc hole in the automobile braking system directly affects the braking effect and safety.

2. Reduce production costs

Although the investment in boring processing equipment is relatively large, due to its high processing accuracy and high efficiency, it can reduce subsequent processing procedures and scrap rate, thereby reducing production costs.

In the food industry, high-precision hole processing can improve the sealing and stability of food processing equipment and reduce food waste and contamination. At the same time, it can also reduce equipment maintenance costs and replacement frequency. For example, the accuracy of the sealing holes on the food packaging machine directly affects the quality and efficiency of the packaging.

3. Enhance product competitiveness

In today's increasingly fierce market competition, product quality and performance are the keys to an enterprise's competitiveness.

Boring processing can provide enterprises with high-precision, high-quality products and enhance their market competitiveness. For example, in the stage lighting equipment market, high-quality optical components and electronic components require high-precision mounting holes, which can only be met by boring processing. By adopting boring processing technology, companies can improve the quality and performance of their products and win more market share.

As a modern mechanical processing method, boring processing has the characteristics of high processing precision, wide adaptability, high processing efficiency, and the ability to process complex holes. It also has the advantages of improving product quality, reducing production costs, and enhancing product competitiveness. It is widely used in the automotive field, food industry, stage lighting and other industries. With the continuous advancement of science and technology, boring processing technology will continue to innovate and develop, providing better processing services for the development of various industries.

Key Words