The role of planing in mechanical manufacturing

Release time:

2024-11-19

This article explains the role of planing in mechanical manufacturing, including its applications in life sciences, smart industry, and automotive fields, as well as its advantages in terms of precision and cost.

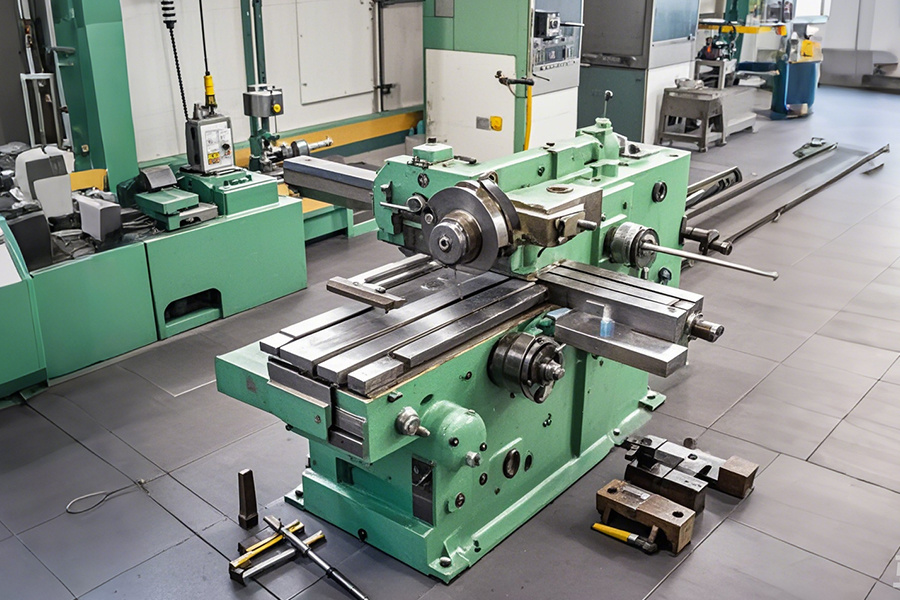

In the vast field of digital controlled mechanical processing, planing is a bright but unique pearl, which plays an indispensable role in the process of mechanical manufacturing and plays a vital role.

Guarantor of high-precision processing

Planing, with its unique processing method, has brought high-precision possibilities to mechanical manufacturing. In the field of life sciences, the manufacture of many precision instruments is inseparable from planing. For example, the high-precision microscope stage used for biological sample analysis has extremely high flatness requirements. Planing can accurately remove materials through the relative linear motion of the tool and the workpiece, ensure the flatness and straightness of the stage surface, so that the microscope can provide a stable and accurate platform when observing the sample, and provide reliable data support for life science research. In the intelligent industry, the shells and internal structures of some sensors also require high-precision processing. Planing can ensure the dimensional accuracy of these parts, so that the sensors can sense and transmit information more accurately.

Shaper of complex shapes

Planing has unique advantages in shaping complex shapes. In the automotive field, in the processing of complex parts such as engine cylinders, planing can be used to process the plane of the cylinder and some special shapes of grooves. It can manufacture complex structures that meet the high-performance operation of automobile engines by adjusting the movement paths of tools and workpieces according to design requirements. For some automobile parts with special requirements, such as the mounting surface of high-performance brake discs, planing can accurately process the required shape to ensure the stability and reliability of the brake system. In the automated production line equipment of intelligent industry, there are also a large number of parts with different shapes that need to be processed. Planing can meet the processing needs of these complex shapes and ensure the smooth operation of the production line.

The embodiment of material adaptability

Planing has a wide range of adaptability to materials, which is of great significance in mechanical manufacturing. Whether it is medical device parts made of high-strength and corrosion-resistant materials such as titanium alloys commonly used in the field of life sciences, or aluminum alloys, alloy steels and other materials used in large quantities in the automotive field, planing can cope with it easily. During the processing process, the planing tool can be selected and adjusted according to the characteristics of different materials to ensure that while removing the material, it will not have an adverse effect on the performance of the material. For example, when processing the aluminum alloy cylinder head of an automobile engine, planing can complete the processing of the cylinder head surface and internal structure while ensuring the strength and sealing of the material, so that the engine can operate normally. In the intelligent industry, planing can also play its strong material adaptability characteristics for the processing of parts such as electronic component shells of different materials.

Cost-effectiveness balancer

In mechanical manufacturing, cost-effectiveness is a factor that enterprises must consider, and planing has an outstanding performance in this regard. Compared with some high-cost processing methods, planing equipment is relatively simple and has a low investment cost. In the large-scale production of automotive parts, by reasonably arranging the planing process, the production cost can be reduced while ensuring quality. In the manufacture of life science instruments, for some small and medium-sized batches of production, planing can reduce processing costs while meeting precision requirements. In the manufacturing of parts for intelligent industry, planing can also achieve a balance of cost-effectiveness and improve the competitiveness of enterprises on the basis of meeting complex shapes and precision requirements.

Fusion with digital control

In today's era of digital control mechanical processing, planing is also actively integrated with digital technology. Through the CNC system, planing can achieve more accurate tool path control, processing parameter adjustment, etc. On the engine production line in the automotive field, CNC planing machine tools can process engine parts efficiently and accurately according to pre-set programs. In the manufacturing of life science instruments, digitally controlled planing can achieve precise processing of tiny sizes and complex shapes. In the intelligent industry, this integration allows planing to better adapt to the automated and intelligent production mode and improve production efficiency and quality.

Planing plays multiple roles in mechanical manufacturing, including the guarantor of high-precision processing, the shaper of complex shapes, the embodiment of material adaptability, the balancer of cost-effectiveness, and the integrator with digital control. Whether in the field of life sciences, intelligent industry or automobiles, planing has made important contributions to the development of the mechanical manufacturing industry with its unique advantages.

Key Words