CTT Machinery: Unveiling the Precision Processing Technology of Oil Tank Sheet Metal Parts

Release time:

2024-11-18

Chuntian Machinery focuses on fuel tank sheet metal processing, from strict material selection, precision cutting, bending forming, high-quality welding to environmental protection treatment, with strict procedures. Advanced equipment guarantees accuracy, perfect testing, creates high-quality products, meets market demand, and provides efficient solutions.

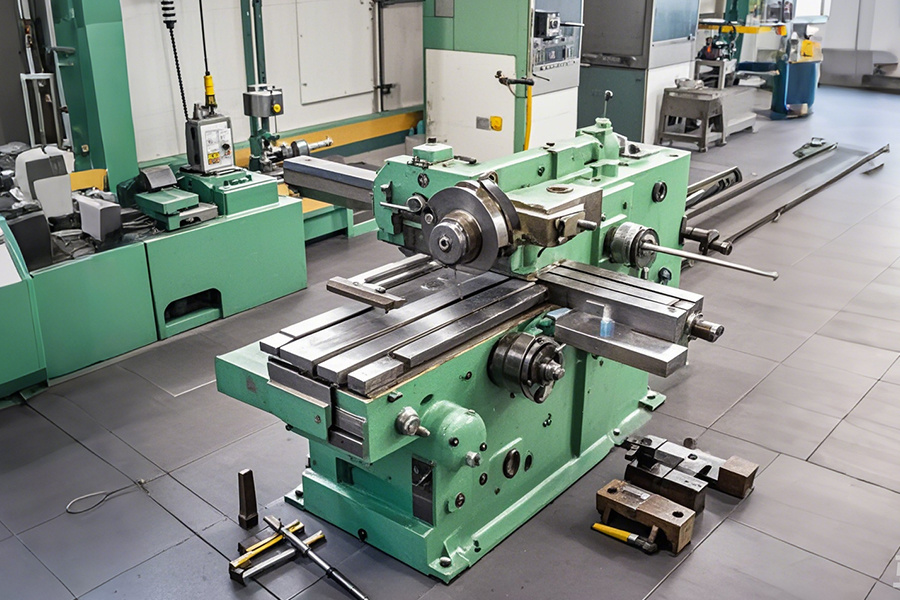

CTT Machinery is equipped with a variety of high-precision mechanical equipment, including German TRUMPF laser cutting machines, OTC laser welding equipment, AMADA CNC punching machines and bending machines, various tonnage precision punching machines, HAGER riveting machines, and a complete set of sheet metal processing equipment and fully automatic spraying production lines. These high-performance devices can handle complex cutting, punching and bending operations, ensuring the accuracy of the part models and laying the foundation for subsequent assembly and integration. In addition, the company is also equipped with advanced inspection equipment, such as three-coordinate measuring machines, projectors, high-power microscopes, salt spray testers, etc., to ensure that each product can meet high-quality standards.

- Strict selection of high-quality materials to ensure product strength

In the material selection of oil tank sheet metal parts, CTT Machinery is extremely strict, mainly selecting high-quality carbon steel as the raw material. These materials undergo strict quality inspections to ensure no cracks, no slag inclusions and other defects. The tensile strength reaches more than 400 MPa and the yield strength is not less than 235 MPa, meeting the strict strength requirements of oil tank sheet metal parts. - High-precision cutting to improve production efficiency

CTT Machinery has multiple advanced laser cutting machines and CNC punching machines, which can achieve high-precision and high-efficiency blanking and cutting. The laser cutting machine adopts a fiber laser, with a cutting speed of up to 100 m/min and a cutting accuracy controlled within ±0.1 mm, effectively improving the material utilization rate and production efficiency. - Fine bending and forming to ensure dimensional accuracy

In the bending and forming process, CTT Machinery uses CNC bending machines for precise bending. This equipment has multi-axis linkage functions and can achieve bending and forming of complex shapes. According to statistics, the annual processing volume of CTT Machinery's CNC bending machines can reach hundreds of thousands of pieces, and the bending accuracy is controlled within ±0.02, ensuring the dimensional accuracy and shape consistency of oil tank sheet metal parts. - High-precision welding to ensure connection strength

Welding is a key link in the processing of oil tank sheet metal parts. CTT Machinery adopts OTC laser welding equipment and TIG welding technology to achieve high-precision and high-quality welding. According to statistics, the weld strength of laser welding can reach more than 90% of the base metal strength, and the welding deformation is small and the heat affected zone is narrow. During the assembly process, the company also adopts advanced positioning and clamping devices and automated assembly lines to ensure the precise fit and stable connection between each component. - Environmentally friendly surface treatment to improve product performance

To improve the corrosion resistance and aesthetics of oil tank sheet metal parts, CTT Machinery adopts the powder spraying technology without three wastes and pollution for surface treatment. This technology has the advantages of uniform coating, strong adhesion and good corrosion resistance. According to statistics, the corrosion resistance time of oil tank sheet metal parts treated with this technology in salt spray tests can reach more than 1000 hours. In addition, the company is also equipped with advanced detection equipment to conduct strict dimensional measurements and appearance inspections on the finished products to ensure that each product meets high-quality standards.

With strict material selection, precise blanking and cutting, fine bending and forming, high-quality welding and assembly, as well as professional surface treatment and quality inspection, CTT Machinery has successfully created a series of high-quality and high-precision oil tank sheet metal part products. In the future, with the continuous progress of technology and changes in market demand, CTT Machinery will continue to uphold the spirit of innovation, constantly improve the technical level and service quality, and provide customers with more high-quality and efficient oil tank sheet metal part solutions.

Key Words