Flexible Manufacturing in Sheet Metal Processing: The Path to Diversified Production

Release time:

2024-12-13

In the field of thin metal plate processing, flexible manufacturing is on the rise. With intelligent processing units, robot collaboration and information management, it breaks through traditional limitations, quickly switches processing tasks, promotes diversified production in the automotive, electronics and other industries, leads the trend of processing innovation, and enhances corporate competitiveness.

In the field of sheet metal processing, with the increasing diversification and personalization of market demand, flexible manufacturing is gradually becoming the mainstream trend, opening up a broad road for enterprises to achieve diversified production.

Traditional sheet metal processing often relies on fixed production lines and processes. When facing the processing needs of different products, it takes a lot of time to adjust equipment and change processes, which is inefficient and costly. Flexible manufacturing is completely different. It has high flexibility and adaptability as its core features.

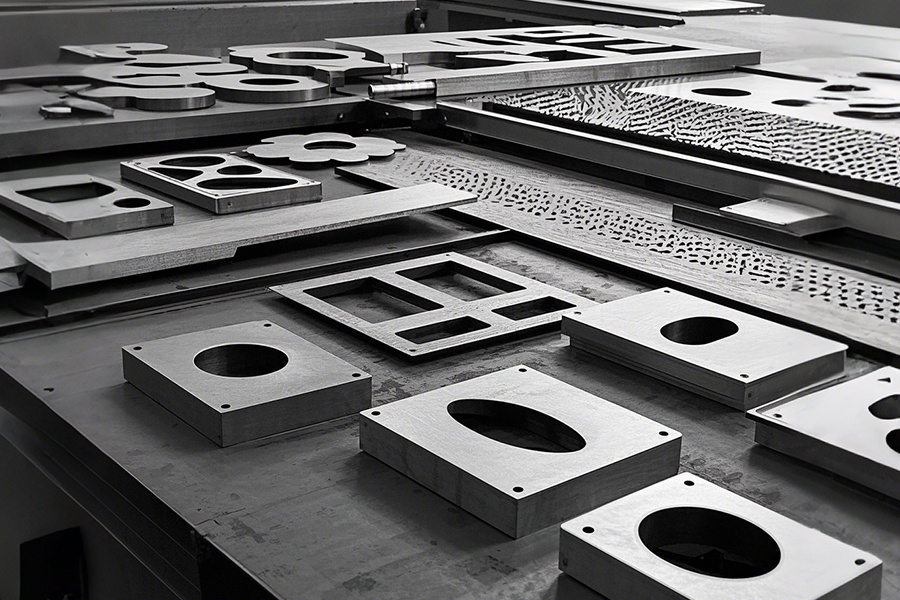

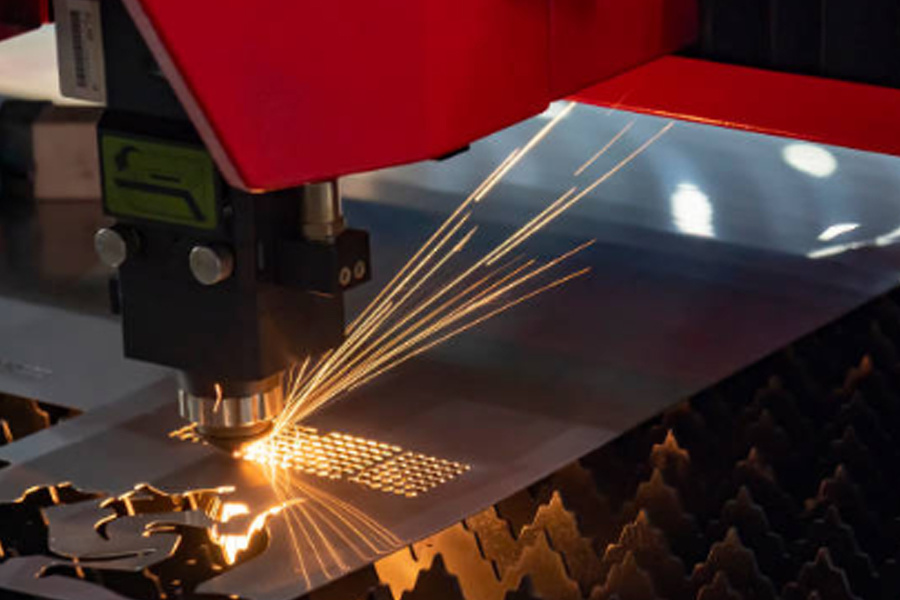

Flexible manufacturing systems are usually composed of multiple intelligent processing units. These processing units have the ability to quickly switch processing tasks. For example, in the cutting of sheet metal, advanced laser cutting equipment is used, which can quickly adjust parameters such as laser power, cutting speed and cutting path through a computer control system according to the requirements of different sheet materials, thicknesses and cutting shapes. When switching from cutting ordinary carbon steel sheets to cutting stainless steel sheets, the system can automatically optimize parameters to ensure that cutting quality and efficiency are not affected.

Flexible manufacturing also performs well in the bending process. Some modern CNC bending machines can store a variety of bending process programs. For metal sheets of different shapes and sizes, they can quickly call the corresponding programs and automatically adjust the angle and position of the bending mold. This means that whether it is the production of simple right-angle bending thin plate parts or complex multi-segment bending special-shaped parts, it can be efficiently completed on the same equipment without long equipment debugging and mold replacement.

Robotics also plays a key role in flexible manufacturing of metal sheet processing. Intelligent robots can accurately grasp and carry metal sheets and collaborate between different processing stations. They can flexibly adjust the handling path and operation sequence according to changes in production tasks. For example, in a workshop where multiple metal sheet products are processed at the same time, robots can transport thin sheet materials to various processing units such as cutting, bending, and welding in an orderly manner according to the production plan, and after processing, they can move the finished products to the designated inspection and packaging area.

Flexible manufacturing is also reflected in the production management level. With the help of advanced information management systems, enterprises can monitor the entire metal sheet processing process in real time. From the inventory management of raw materials to the progress tracking of each processing step, to the quality inspection data record of the finished product, all can be seen at a glance in the management system. When market demand changes and the production plan needs to be adjusted, the management system can quickly re-plan the production process, reasonably allocate resources, and ensure the continuity and efficiency of production. For example, if a customer temporarily increases the order quantity of a certain metal sheet product, the management system can quickly evaluate the existing production capacity, adjust the production priority of other products, arrange overtime or increase the equipment operation time to meet customer needs.

In the automotive manufacturing industry, the advantages of flexible manufacturing of metal sheets are particularly obvious. Different parts of the car body require metal sheet parts of various shapes and specifications. The flexible manufacturing system can quickly respond to design changes and production demand adjustments, and produce the sheet parts required for multiple models on the same production line, greatly shortening the research and development and production cycle of new models. In the field of electronic equipment manufacturing, the diverse design requirements for metal sheet shells can also be efficiently met through flexible manufacturing. Whether it is a delicate sheet shell for a small handheld device or a metal sheet structure for a large electronic cabinet, it can be flexibly produced.

Flexible manufacturing in metal sheet processing has broken the limitations of traditional processing modes through the synergy of intelligent processing units, robot collaboration, and information management, achieved diversified production, and improved the market competitiveness of enterprises. It is an important development direction for the metal sheet processing industry to move towards an intelligent and efficient future.

Key Words