Under the wave of intelligent manufacturing, the collaborative evolution of the sheet metal process chain

Release time:

2025-06-09

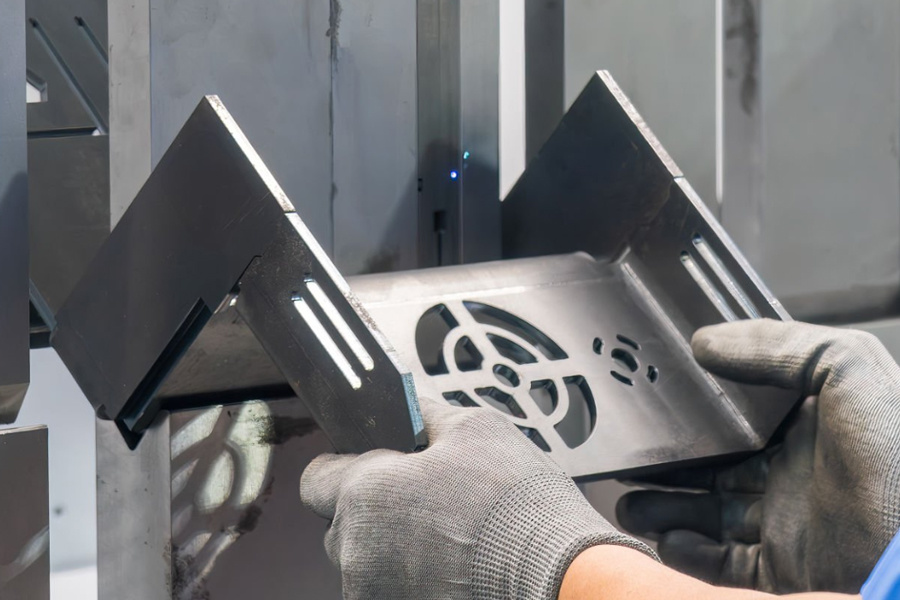

Improve the connection strength and product durability through personalized welding solutions, automated production lines and flexible production capabilities. Article introduction: Modern sheet metal processing builds a precision manufacturing network through multi-dimensional processes to realize the full process solution from material forming to precision processing. Through core processes such as welding, stamping, bending, laser cutting, etc., the connection strength and precision are effectively improved. It has shown significant advantages in both batch forming and small batch customization.

In the process of intelligent upgrading of manufacturing industry, the demand for precision and integration in the field of metal processing is driving industrial innovation. As a key link in industrial manufacturing, the sheet metal processing system provides a full-process solution from material forming to precision processing for various industries through the deep collaboration of core processes such as welding, stamping, bending, and laser cutting. This article will explore the differentiated value of modern sheet metal processing and help enterprises build an efficient supply chain.

Multi-dimensional process builds a precision manufacturing network

1. Sheet metal welding: the art of reliability of metal fusion

Welding is the "structural bond" of sheet metal processing, and processes such as argon arc welding and gas shielded welding are used to achieve a stable combination of metal materials. For plates of different thicknesses and special alloys, customized welding solutions can significantly improve the connection strength. From flat components to complex curved components, mature processes combined with non-destructive testing technology provide important guarantees for product durability.

2. Sheet metal stamping: efficiency innovation of batch forming

The stamping process relies on the collaboration of high-precision molds and CNC equipment to achieve efficient conversion of metal sheets. It can maintain excellent dimensional stability on a variety of materials from ultra-thin stainless steel to medium-thick carbon steel. Automated production lines support rapid mold change, especially suitable for large-scale production scenarios such as automotive parts and electronic equipment housings. Advanced mold development capabilities can significantly shorten product trial production cycles.

3. Sheet metal bending: Precision control of spatial shaping

The bending process uses a CNC system to precisely control metal deformation to achieve multi-angle complex shaping. Dynamic compensation technology effectively improves molding accuracy for the rebound characteristics of materials such as aluminum alloys and galvanized sheets. From basic brackets to multi-curvature components, flexible production capabilities meet the precise appearance requirements of medical devices, new energy equipment and other fields.

4. Laser cutting: Intelligent deconstruction of complex contours

Laser cutting reshapes processing boundaries with excellent positioning accuracy. Fiber optic technology can efficiently process materials such as carbon steel, stainless steel and aluminum alloys to achieve clean cutting of complex graphics. The intelligent programming system is compatible with mainstream design formats and optimizes material utilization with automatic typesetting. The mold-free production feature gives it a significant advantage in the field of small-batch customization.

Strategic value of integrated services

Facing the demand for complex component processing, the full-process service model highlights three core advantages:

● Process synergy and efficiency: avoid multi-link connection losses and shorten product delivery cycle

● Quality control throughout the process: unified standards run through the entire process of welding/stamping/bending/cutting

● Comprehensive cost optimization: resource intensiveness reduces unit cost and improves input-output ratio

Mature service providers can also provide value-added services such as material selection and surface treatment to help customers achieve seamless transformation from design to finished products.

Dimensional reference for preferred processing partners

● Technical integration capabilities: focus on the level of multi-process composite implementation

● Digital response mechanism: online order management system improves collaboration efficiency

● Quality assurance system: perfect testing process and process control capabilities

Collaborative innovation drives manufacturing upgrades

Against the background of the deepening development of intelligent manufacturing, sheet metal processing is evolving from single-point processes to system solutions. When welding reliability, stamping efficiency, bending accuracy and laser cutting intelligence are deeply integrated, this process chain collaboration model will continue to enable innovation and development in high-end equipment, new energy, electronic technology and other fields.

Key Words