Why has sheet metal processing become an industrial necessity?

Release time:

2025-06-10

In the modern industrial system, sheet metal processing occupies a core position, with high material utilization, strong process chain plasticity, and significant cost advantages. It has a dominant position in price-sensitive industries such as automobile manufacturing, consumer electronics, and home appliances.

Sheet metal processing occupies a core position in the modern industrial system, and its irreplaceability stems from the technical advantages of three dimensions. First, the process shows a significant material utilization rate in metal material processing (generally above 92%). According to processes such as precision stamping and bending, the loss of raw materials is 40%-60% lower than that of casting. Secondly, it covers key fields such as the automotive industry, consumer electronics, and aerospace engineering. According to statistics, the sheet metal demand for each new energy vehicle reaches 120-150 pieces, accounting for 35% of the total automotive parts. With the implementation of Industry 4.0, the intelligent sheet metal production line will increase the processing efficiency to 3.2 times that of the old method, while achieving ±0.05mm precision control, supporting flexible production requirements.

Producing spacecraft fuel tanks

It is worth noting that the plasticity of the process chain enables it to quickly meet the processing requirements of new materials. For example, in the construction of 5g base stations, the utilization rate of aluminum-magnesium alloy sheet metal has exceeded 78%. The integration of this technical feature and cost structure constitutes a basic competitiveness that is difficult to replicate in the modern industrial system.

Advantages of sheet metal processing material cost Advantages Advantages Advantages

Compared with other forming methods, sheet metal processing shows significant competitiveness in terms of raw material utilization. Based on precise stamping, bending and cutting technology, the processing cost of metal materials is generally maintained below 5%, and the waste rate of forging or injection molding materials is generally more than 15%. This kind of efficient material utilization immediately reduces the marginal benefits of bulk products, especially in mass production scenarios, the total savings can reach millions. Taking the automotive industry as an example, when selecting sheet metal processing, one ton of steel can produce about 300 standard parts, while the traditional forging solution can only produce about 220 standard parts. In addition, sheet metal processing has significant adaptability to the thickness of metal materials. Enterprises can flexibly choose materials such as galvanized sheets, stainless steel or aluminum alloys according to their needs, without being forced to purchase high-priced special alloys due to process limitations, further reducing supply chain costs. Industry data shows that the comprehensive manufacturing cost of sheet metal is 30%-40% lower than that of castings, and it occupies a dominant position in price-sensitive industries such as consumer electronics and home appliances.

Analysis of important cross-field applications

The widespread use of sheet metal processing technology stems from its precise forming level and highly personalized characteristics. In the field of automobile manufacturing, from the body to the chassis structure, high-precision bending and stamping processes ensure the balance between strength and lightness of parts. For example, after the battery shell of the battery car adopts the sheet metal process, the net weight is reduced by 12%, while maintaining the IP67 waterproof level. With the help of the thin plastic shell manufacturing process, the electronic equipment industry mass-produces 0.3mm thick aluminum alloys based on continuous die stamping to meet the multiple requirements of smartphone heat dissipation and electromagnetic shielding. In the field of aerospace, sheet metal technology is perfect. Based on the progressive forming technology, the engine fairing achieves a 0.05mm tolerance control on the titanium alloy plate, effectively coping with extreme temperature and pressure environments.

When choosing sheet metal processing services, enterprises are advised to give priority to the integrity of the process database of the target main use supplier, which will affect the output and delivery cycle of complex parts.

With the improvement of the requirements for sterile environment in medical equipment, the integrated forming technology of stainless steel sheet metal parts has replaced the traditional welding process, and the airtightness of surgical instrument boxes has been improved to 99.98%. This kind of cross-industry penetration capability makes sheet metal processing a bridge connecting basic production and high-end equipment, and the continuous development of its application scenarios continues to consolidate the core position of the industrial value chain.

Intelligent upgrade strengthens strategic position

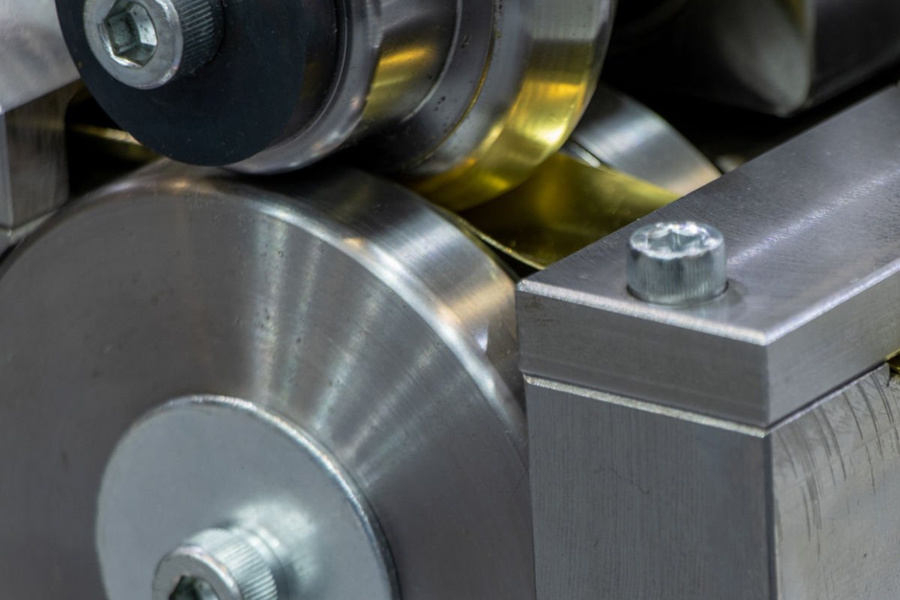

With the penetration of the industrial 4.0 technology framework, sheet metal processing has achieved a leap in productivity based on intelligent transformation. By introducing intelligent products such as laser cutting CNC lathes and responsive bending robots, the company can accurately control the 0.1mm tolerance and reduce the raw material loss rate to less than 60% of the traditional process. The application of digital twin technology forms a closed loop between process simulation and physical processing, shortens the new product development cycle by more than 40%, and significantly improves the responsiveness to handle customized needs.

In terms of system integration, the Internet of Things promotes the production monitoring platform to achieve equipment interconnection and data transmission, and real-time tracking of key indicators such as energy consumption and working hours in the entire production. This kind of deep intelligence not only improves the efficiency of resource allocation, but also continuously improves process indicators through machine learning algorithms, so that the output of complex parts is maintained above 98.5%. It is worth noting that the intelligent upgrade does not weaken the flexibility of sheet metal processing, but realizes the economy of small batch and multi-variety production based on modular programming, adding precision and flexibility solutions to the industrial manufacturing system.

Irreplaceable process discussion

The core reason why sheet metal processing is irreplaceable in the modern industrial system is first reflected in its efficient processing of complex parts. Whether it is the integrated forming of the chassis or the precision bending of the electronic equipment housing, traditional forging or injection molding processes are difficult to achieve the same level of material utilization and dimensional accuracy. Secondly, the unique strength and ductility structure of metal materials can not only withstand mechanical stress, but also meet diversified modeling requirements. The deep binding of such material properties and processing technology has formed an unrepeatable technical requirement. At the same time, the flexible response advantage of sheet metal processing in small and medium batch production can quickly meet product iteration requirements, but in mass production scenarios, the cost control of emerging technologies such as 3D printing is still obviously insufficient. It is worth noting that the introduction of smart products and digital twin technology has further improved the stability of the technology, making traditional sheet metal processing more industrially dynamic.

The core position of sheet metal processing in the modern industrial system essentially stems from its ability to respond to complex demands. From the economic selection of basic materials to the innovation of precision forming technology, the process balances the differences in efficiency and accuracy through continuous iteration. In response to the transformation of production models caused by Industry 4.0, the integration of smart products and digital processes has not weakened their value, but optimized processing technology decisions through real-time data feedback. In the trend of lightweight design of automobiles and miniaturization of electronic equipment, the physical characteristics and production flexibility of metal materials cannot be completely replaced by injection molding or 3D printing. The emergence of this process not only shows the vitality of traditional manufacturing technology, but also reveals the development law that technology accumulation in the process of industrial evolution is not a simple replacement.

Key Words