From drawings to objects: How does sheet metal processing turn designers' ideas into reality?

Release time:

2025-06-12

Sheet metal processing is the process of converting design drawings into mass-producible process paths. Precision cutting processes mainly use technologies such as laser, plasma or water jet to achieve millimeter-level tolerance control. Parametric design opens up a collaborative channel between engineering data and production equipment through 3D modeling, ensuring high-fidelity conversion of creative ideas and physical objects.

Sheet metal processing is a systematic project to transform flat metal sheets into three-dimensional structural parts. Its core lies in gradually transforming the geometric parameters and functional requirements in the design drawings into a process path that can be mass-produced. The process starts with the precise analysis of the design drawings, optimizes the part development drawings through digital modeling tools, and then enters the material cutting and forming stage. The precision cutting process achieves millimeter-level tolerance control through technologies such as laser, plasma or water jet, while the bending forming technology relies on CNC equipment to shape the angles and arcs of the sheet in multiple dimensions. In this process, 3D modeling not only provides visual support for process simulation, but also opens up the collaborative channel between engineering data and production equipment through parametric design to ensure the high-fidelity transformation of creative ideas and physical objects.

Design Drawing Conversion Process

Sheet metal processing begins with the systematic analysis and engineering conversion of design drawings. The technical team first receives the design files containing dimensioning, tolerance requirements and structural features, and uses professional software to perform 3D reconstruction and process feasibility verification on the drawings. At this stage, engineers need to focus on reviewing core parameters such as material thickness, bending radius, and hole distribution to ensure that they meet industry processing specifications and equipment performance boundaries. For complex curved surfaces or special-shaped structures, parametric modeling technology is often used to adjust the original design to process adaptability, such as increasing the bending compensation value to avoid dimensional rebound deviation after forming. At the same time, the material utilization optimization module will automatically generate a nested layout plan based on the part contour to minimize the loss of metal sheets. After completing the digital verification, the process file package will associate the cutting path code, bending sequence logic and fixture configuration parameters to establish an accurate instruction system for subsequent physical processing.

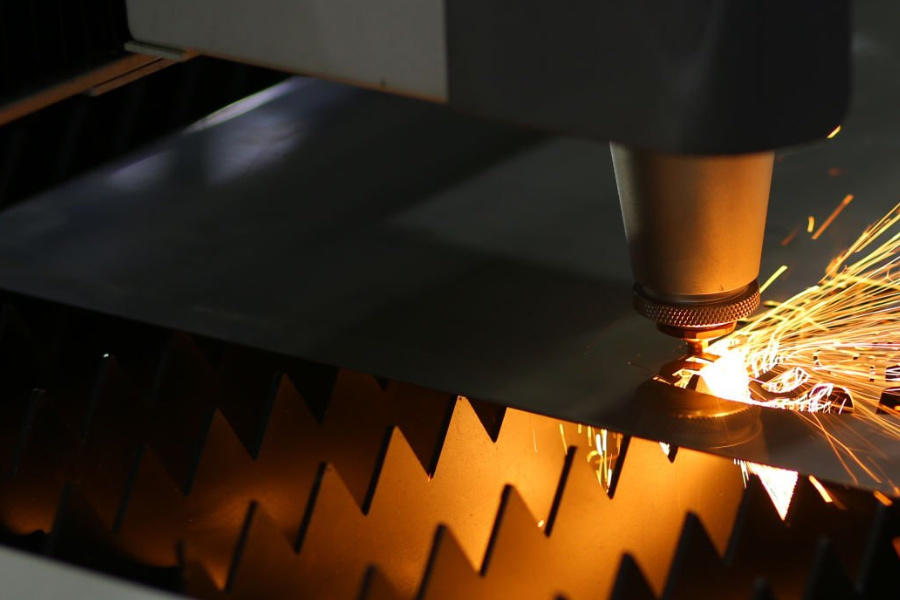

Precision cutting process revealed

After completing the digital transformation of the design drawings, sheet metal processing officially enters the core link of the production stage-precision cutting. This process converts flat metal sheets into a part base of a predetermined shape through high-precision equipment, and its cutting accuracy can reach ±0.1mm, laying a key foundation for subsequent processes. As a mainstream technology, laser cutting can achieve non-contact cutting of materials such as stainless steel and aluminum alloys with a thickness of 0.5mm to 25mm with its high energy density of focused beams, effectively avoiding material deformation. Water jet cutting is suitable for special alloys that are sensitive to heat. It uses ultra-high pressure water flow mixed with abrasives to complete the processing of complex contours, and the smoothness of the cut is better than that of traditional mechanical cutting. It is worth noting that modern intelligent cutting systems have achieved direct docking with 3D modeling data, and optimize the cutting path through algorithms, which greatly shortens the processing cycle while improving material utilization by 15%-30%. The refined control of process parameters (such as cutting speed, air pressure value, and focal position) has become the core element of balancing efficiency and quality, and directly affects the assembly accuracy and surface finish of the finished product.

Analysis of bending forming technology

On the basis of completing the precision-cut sheet metal parts, bending forming has become the core link of structural finalization. The hydraulic bending machine uses a high-pressure hydraulic system as the power source, converts mechanical energy into hydraulic energy through a hydraulic pump, and transmits it to the hydraulic cylinder through a pipeline to push the slider for bending operations. This power output method can provide continuous, stable and strong pressure, with a maximum pressure of thousands of tons, which can easily cope with the bending needs of difficult-to-process materials such as high-strength alloy steel and thick steel plates. During the processing, the hydraulic system can accurately adjust the pressure value according to the material and thickness of the sheet to ensure that the bending angle and curvature are accurate. At the same time, with the high-precision servo control system, the angle control accuracy of the hydraulic bending machine can reach ±0.1°, and the repeat positioning accuracy is better than ±0.05mm, which provides a reliable guarantee for the high-quality forming of complex sheet metal parts.

3D modeling drives manufacturing

In modern sheet metal processing, 3D modeling technology has become the core hub for connecting design and production. Through the digital model built by professional software such as SolidWorks and AutoCAD, engineers can intuitively present the three-dimensional structure of the product, accurately mark the dimensional tolerance and assembly relationship, and significantly reduce the interpretation error of traditional two-dimensional drawings. Under the parametric design framework, the model supports dynamic adjustment of key parameters such as bending angle and opening position, and detects the interference risk between components through virtual assembly, and optimizes the process plan in advance. In addition, 3D data can be directly connected to laser cutting machines and CNC bending equipment to generate machine-recognizable processing path codes, realizing seamless command transmission from model to machine tool. This data intercommunication mode not only improves processing accuracy, but also shortens the product iteration cycle, providing technical support for the multi-variety and small-batch production of complex sheet metal parts.

Looking at the complete chain of sheet metal processing from drawings to finished products, the accurate transmission of design intent always depends on the deep integration of technology and process. The digital transformation of design drawings not only defines the physical boundaries for precision cutting, but also predicts the deformation law of materials through dynamic simulation of three-dimensional modeling, and the precise control of bending forming technology becomes the key node for balancing structural strength and morphological accuracy. With the iterative upgrade of CNC systems and intelligent algorithms, modern manufacturing processes are gradually breaking through the limitations of traditional processing, while improving product consistency, it also releases greater creative space for designers. This continuous dialogue between engineering thinking and artistic expression ultimately promotes the precise transition of metal sheets from flat drawings to three-dimensional objects.

Key Words